Posted Date : 18 September 2025

Posted by : Parul Atri

The industrial world is experiencing its most fundamental transformation since the steam engine. Industry 5.0 is the upcoming revolutionary phase, especially in manufacturing, that has created a shift from Industry 4.0 to human-robot partnership. Unlike the pure automation, which has readily prioritized efficiency through the Internet of Things (IoT) and artificial intelligence (AI), Industry 5.0 has emphasized resilience, sustainability, and human creativity. With this evolution, businesses can highlight real-world impacts, including a safe workplace, green manufacturing, and customized products. This sets the stage to gain deep insight by framing Industry 5.0 as the ultimate balance between humanity and technology.

Let us take a deep dive and readily explore core technologies, smart factories, benefits and challenges, along with the future scope of the Industry 5.0.

What Is Industry 5.0?

There is a new revolutionary game in the technology industry other than Industry 4.0, which is Industry 5.0. It is effectively flipping automation by positioning human beings in the driver’s seat. It is not just about cold and robot-based factories; instead, it is all about cobots, known as collaborative robots, operating jointly with people and creating a fusion of machine precision with human creativity. This technology has taken things further, wherein almost 75% of manufacturers hold the opinion that this robot-human collaboration is crucial for further growth.

Furthermore, organizations utilizing cobots have witnessed a 55% increase in production time in comparison to Industry 4.0. In addition, there has been 62% less wastage in circular production models. Besides, cobot-based factories of BMW have achieved a 17% boost in productivity, while Adidas’s recycled-material sneakers successfully saved 11,500 tons of plastic waste with the implementation. The bottom line is that Industry 5.0 is not just an upgradation but a full-blown revolution, with human ingenuity, sustainability, and ethics taking the center stage.

Robots and Humans - The Ultimate Power Duo

Industry 5.0’s cobots have taken the responsibility to supercharge human potential, and not just replace it! Here, we are talking about uninterrupted human-robot teamwork that has bolstered productivity by 35% to 55%. The aspect of safety revolution and smart task sharing are two main factors behind this collaboration.

Safety Revolution

With AI-driven smart sensors and exoskeletons, workplace hazards have been reduced by 72.5% in cobot-equipped facilities. Based on this, Amazon warehouses currently utilize robot pickers that can replace the human approach automatically. Besides, there has been a rise in robot whisperers, deliberately earning USD 88,000 every year, along with AI ethics officers, which has increased up to 145% since 2022. This has readily proved that technology has developed more roles than eliminating them.

Smart Task Sharing

Cobots have the ability to handle repetitive and critical tasks, including heavy lifting and welding, while humans can readily tackle inventive problem-solving circumstances. For instance, Tesla factories have proven this on a daily basis, wherein an estimated 95% of welding has been initiated by robots, while engineers have optimized production flow procedures. This has been possible with Industry 5.0, thus bringing in innovation.

How Industry 5.0 Makes ‘Made Just For You’ the New Normal?

Industry 5.0 has unleashed a personalized revolution, wherein each product can be a customized masterpiece without the need for a luxury price tag. The credit for this goes to mind-blowing technology, based on which different brands can deliver customization on a large scale, by converting scientific dreams into reality.

- AI design wizards: Now imagine algorithms that are aware of your style better than other people. For instance, the Nike By You concept of Nike permits consumers to design 11.5 million sneaker combinations, while the Share-a-Coke campaign by Coca-Cola has driven a 2.5% boost in worldwide sales just by printing names on its bottles.

- 3D printing magic: Dental laboratories currently print more than 50,500 personalized implants regularly, and startup firms, such as Unmade, have crafted knitwear that is tailored to customers’ measurements with the absence of fabric wastage.

- Digital twin perfection: People who purchase cars at BMW have configured interiors in VR before the production process, which has diminished returns by approximately 35%. Likewise, Dell’s customized PCs make use of digitalized twins to ensure flawless operations without any technical disparities.

All these aspects of hyper-personalization matter, since almost 88% of customers spend more on custom products. In addition, the zero-waste production process has reduced expenses by approximately 18% to 22%, and lead time has diminished from weeks to hours. Therefore, with Industry 5.0, personalization is not the future, but the present!

Industry 5.0 Making Factories Sustainable than a Tesla Cybertruck

Industry 5.0 is tossing manufacturing from planet-killer to plant-saver, so eco-warriors, just hold onto your reusable water bottles. Here, our focus is all about the green revolution, wherein sustainability is not a public relations activity, but a future-proof business and profit-boosting model.

The Holy Trinity of Green Manufacturing

- Circular economies on steroids: Organizations such as Fairphone have developed more than 95% of phones that are repairable, with the latest feature of a pop-in camera module. Meanwhile, the furniture buyback program of IKEA has diverted 1.3 million products from landfills in the previous year.

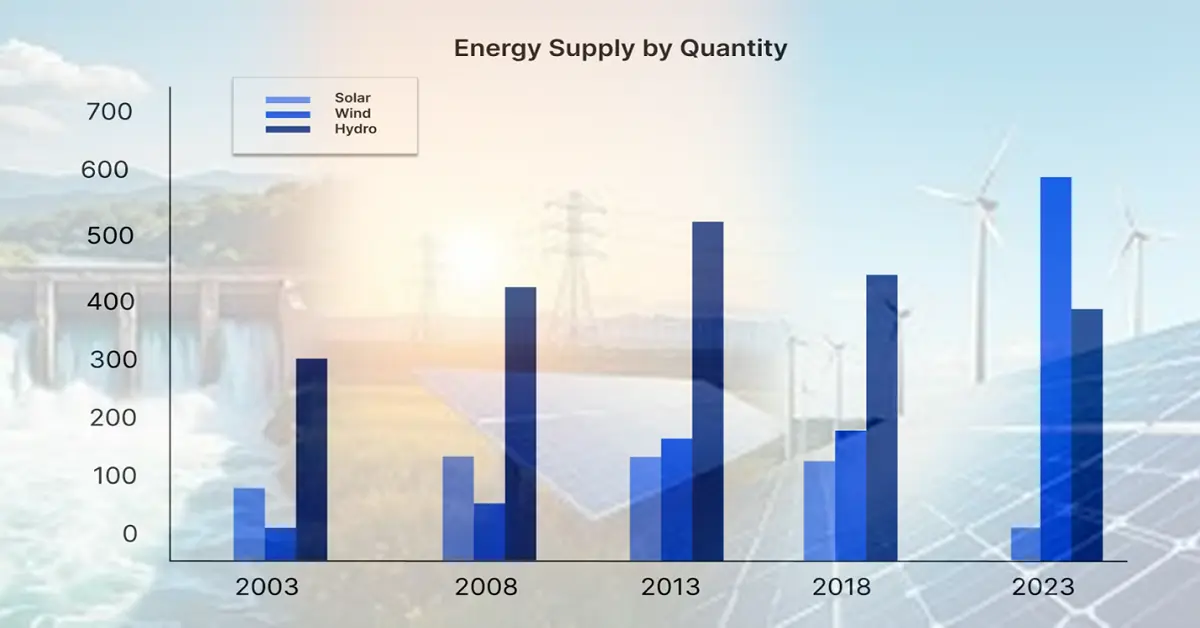

- AI as the energy-saving superhero: Factories are readily implementing AI-driven smart grids, which have lowered power bills by almost 45%. This, in turn, caters to taking 55,000 cars off the road every year for per plant. This is even better since these systems can self-optimize while people are not operating. Besides, Industry 5.0 effectively ensures a national-level energy supply based on quantity to determine digital infrastructure.

Source: MDPI

Source: MDPI

- Recycling robots: This factor plays a vital role in ensuring sustainability across all factories and businesses. For instance, Apple’s Daisy robot tends to disassemble 250 iPhones every hour, and also recovers cobalt and gold with a 95.5% accuracy rate. Similarly, AMP Robotics’ AI classifiers can process almost 85 recyclables every minute, thereby assisting recycling hubs to bolster profit by 35%.

Apart from these components, Ocean Plastic Shoes by Adidas have upcycled more than 3,500 marine waste since previous years. Likewise, Schneider Electric’s smart factories have reduced carbon dioxide by an estimated 50.5% and increased the output process. Not to be overlooked, the aspect of 3D printing diminishes material waste by 93% in comparison to conventional machinery. Therefore, sustainability is the actual competitive edge, and organizations are embracing Industry 5.0’s green technology, which has witnessed a 25% increase in customer loyalty.

The Dark Side of Industry 5.0

Industry 5.0, overall, is all about eco-factories and robot co-workers, but let us dive deep into the real talk. This innovative technology comprises a few critical growing pains, and overlooking them can result in losing millions. Following is the unfiltered truth:

- Cyber-siege alert: Every latest IoT sensor is a probable hacker, and smart factories are facing 3 times more attacks when compared with conventional ones. For example, in November 2022, the LockBit ransomware gang attacked Continental, a German auto supplier, leading to a loss of USD 50 million.

- Limited budget: Small-scale business owners increasingly face this drawback while implementing Industry 5.0. Regarding this, a single cobot can cost between USD 28,000 to USD 52,000 with the feature of full digital transition. Based on this, small and medium-sized enterprises always constitute the feeling of being priced out.

- Job replacement: This has created panic among the global workforce! Industry 5.0 has readily created new roles, and an estimated 50% of workers from across nations fear that they lack the required technical skills. This accounts for exactly half of the workforce, which has the potential to resist modifications.

But if challenges exist, so do solutions! The aspects of government assistance, cyber armor, and upskilling organizations are a few resolutions to combat the above-mentioned encounters. For example, the USD 2.5 billion Industry 4.0 in Germany has currently expanded to Industry 5.0. Meanwhile, with the implementation of cyber armor, AI-driven threat identification tends to reduce 95% of breaches, and the USD 750 million retraining program at Amazon has lowered turnover by 30.5%.

The Future of Work With Industry 5.0

The workplace in the upcoming years will be nothing in comparison to the present day. Remote collaboration, AI, and automation are continuously reshaping industries and developing the latest career options while converting old ones. Here’s what is changing:

Emergence of new careers

The integration of robot supervisors is maintaining and managing AI-powered automation, along with the utilization of augmented and virtual reality to troubleshoot machinery remotely. In addition, AI-based ethics consultants are readily ensuring AI deployment in businesses.

Remote Oversight and Hybrid Work

Engineers are effectively monitoring and evaluating factories through virtual and augmented reality, which has reduced on-site visits. Besides, digitalized twins are virtual replicas of physical systems and devices that permit real-time adjustments from any location. Not to forget, the implementation of hybrid models has blended remote flexibility with vital in-person partnership and collaboration.

Lifelong Learning and Microcredentials

Conventional degrees are deliberately being replaced by skill-focused and short online courses. Besides, organizations, such as Siemens Healthineers, have enhanced the usage of augmented reality, particularly for employee training, and meanwhile Bosch has invested to provide AI skilling to its employees. Therefore, here lies the ultimate takeaway that adaptation is the key to the future workplace and a top skill for further career upliftment in the Industry 5.0 era.

Furthermore, there will be more radical transitions in the upcoming decade. For instance, with AI co-creation, machines will provide assistance in research and development activities, which will accelerate breakthroughs in material science and drug discovery. Additionally, laboratory-grown materials, including spider-silk and mushroom leather fabrics, will replace synthesis through bio-manufacturing that will reduce the environmental impact. Besides, one can only imagine products that can repair cracks or scratches on their own, which will further diminish manufacturing waste and expenses through self-healing materials.

Adapt or Fall Behind with Industry 5.0

The future of industry is here, focusing on hyper-agility, sustainability, and collaborative actions with Industry 5.0. Businesses that ignore this will face risks and hazards, while those integrating circular economies, flexible workflows, and cobots are expected to lead. The key aspect in this transition is to start small, but think big. The aspects of upskilling teams in AI collaboration, evaluating a green manufacturing process, and piloting a cobot deployment system are necessary. Besides, in the human-based era of Industry 5.0, businesses that successfully merge technology with purpose will be successful. Now, the question is not about whether you will adapt, but how soon the adaptation will take place. Eventually, the future belongs to those who embrace modifications, learns, and adapt to!

Contact Us