Superplastic Alloys Market Outlook:

Superplastic Alloys Market size was over USD 20.91 billion in 2025 and is poised to exceed USD 65.53 billion by 2035, growing at over 12.1% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of superplastic alloys is estimated at USD 23.19 billion.

The major factor to influence the sector growth is the growing demand for lightweight materials in the automotive sector. Lightweight materials possess a lot of potential for enhancing vehicle efficiency since they requires less energy to accelerate a lighter item than a heavy one. A 6%–8% increase in fuel efficiency might be obtained with a 10% decrease in vehicle weight.

Moreover, due to superplastic formation, car manufacturers are able to produce intricate parts made of thin and lightweight materials without having to break the budget. This is done by replaying cast iron and conventional steel components with lightweight alternatives including high-strength steel, magnesium (Mg) alloys, aluminum (Al) alloys, and more. This may instantly decrease a vehicle's body and chassis weight by up to 50%, which in turn lowers fuel consumption. As a result, the superplastic alloys market is rising.

Key Superplastic Alloys Market Insights Summary:

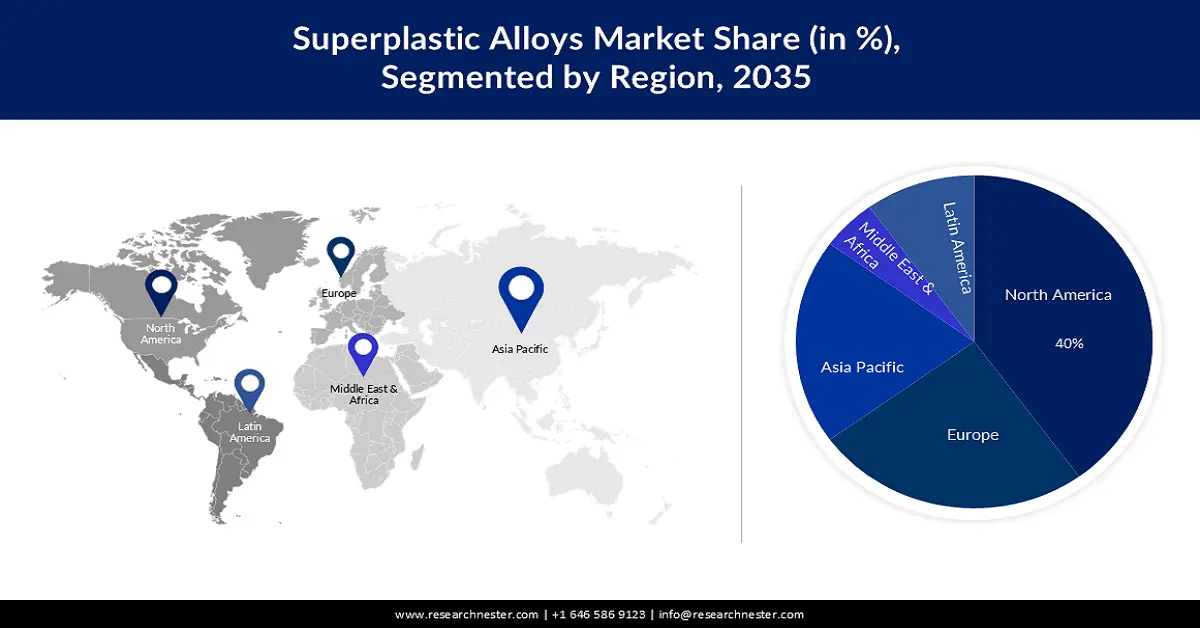

Regional Highlights:

- By 2035, North America is projected to command a 40% share of the superplastic alloys market, attributable to escalating aircraft production.

- Europe is anticipated to secure a notable market share by 2035, owing to rising government initiatives for electric vehicle adoption.

Segment Insights:

- By 2035, the aluminum alloy segment is expected to hold a 30% share of the superplastic alloys market, propelled by rising construction activities.

- Over 2026-2035, the microstructural segment is set to capture about a 60% revenue share, impelled by growing applications in the medical and consumer electronics sectors.

Key Growth Trends:

- Growing Utilization for Superplastic Alloy in Aerospace

- Rising Use of Recycled Superplastic Alloy

Major Challenges:

- Low Rate of Formation of Superplastic Alloy

- Growing Risk of Superplastic Alloy on the Environment

Key Players: ATI, Arconic Corporation, CRS Holdings, LLC., Haynes International, Inc., Materion Corporation, Norsk Hydro ASA, Precision Castparts Corp., Sandvik AB, Thyssenkrupp AG, TimkenSteel Corporation.

Global Superplastic Alloys Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 20.91 billion

- 2026 Market Size: USD 23.19 billion

- Projected Market Size: USD 65.53 billion by 2035

- Growth Forecasts: 12.1%

Key Regional Dynamics:

- Largest Region: North America (40% Share by 2035)

- Fastest Growing Region: Europe

- Dominating Countries: United States, China, Germany, Japan, United Kingdom

- Emerging Countries: India, South Korea, Brazil, Mexico, Indonesia

Last updated on : 19 November, 2025

Superplastic Alloys Market - Growth Drivers and Challenges

Growth Drivers

- Growing Utilization for Superplastic Alloy in Aerospace - The aircraft industry uses superplastic forming as a cost-effective method for producing complicated components to nearly net shape as a single piece. This decreases the number of individual pieces and the assembly costs that are sometimes involved with producing complex components. For many years, the aerospace sector has been employing this forming technology for specialized goods. One of the most significant superplastic alloy materials used in aerospace is titanium. Owing to its toughness, tolerance to high temperatures, and low weight, this material is extensively utilized in the aircraft industry. Additionally, the use of aluminum is also growing rigorously in this sector. Hence, the superplastic alloys market revenue is projected to increase.

- Rising Use of Recycled Superplastic Alloy - The creation of environmentally conscious and sustainable superplastic materials is a current trend in the superplastic materials sector. As the desire to protect the environment becomes more pressing, producers are looking into ways to make superplastic materials that have lower carbon footprints. Green production techniques and the utilization of recyclable resources are instances of recent innovations. This development offers superplastic materials as ethical options for industries that care about the environment and is in line with the global trend towards sustainable practices.

- Surge in the Use of Automation to Produce Superplastic Alloy - As the demand for higher output and cost reduction persists, firms involved in the manufacturing of superplastic alloys are turning to automation and Industry 4.0 solutions to boost their productivity. Various issues which including stock shortages may be prevented from occurring during downtime by employing devices that track materials at a workstation or in inventory. Observing equipment run durations could be sufficient to save downtime by modifying workflow to minimize changeovers, or it could show which areas would benefit from further automation investments. Furthermore, automated equipment increases repeatability, which lowers inconsistency in manufacturing and raises quality. Moreover, with the advancement of digital technologies including IIoT, robots, and machine vision, factory automation is set to grow in the future. Hence, the production of superplastic alloy is set to grow efficiently which would also drive superplastic alloys market expansion.

Challenges

- Low Rate of Formation of Superplastic Alloy

- Growing Risk of Superplastic Alloy on the Environment

- Requires High Investment in the Formation of Superplastic Alloys - Compared to traditional alloys, the formation of superplastic is a slower process and requires more expensive materials. Superplastic forming usually offers a financial benefit when it comes to tiny to medium-sized complex pieces, which are typically made of pricey materials with poor formability. However, in case of huge consignment, the need for great quality materials increases which further also boosts the need for investment. As a result, the manufacturer's preference for traditional alloys might grow which would hinder the adoption of superplastic alloys.

Superplastic Alloys Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Year |

2026-2035 |

|

CAGR |

12.1% |

|

Base Year Market Size (2025) |

USD 20.91 billion |

|

Forecast Year Market Size (2035) |

USD 65.53 billion |

|

Regional Scope |

|

Superplastic Alloys Market Segmentation:

Substrate Material Segment Analysis

The aluminum alloy segment is predicted to hold 30% share of the global superplastic alloys market by 2035. The major factor to dominate the segment expansion is rising construction activities. In 2016, there were projected to be 794,431 built-up areas (BUAs) around the world. This figure is expected to rise to about 849,406 people by 2022. Moreover, by 2050, it's anticipated that 2 million new buildings will be built. Hence, the demand for aluminum alloy is also surging since it is used in developing the lining of buildings. Also, these alloys have the best corrosion resistivity properties. As a result, they are most preferred in the construction sector. Moreover, aluminum alloys that have been superplastically formed, or SPF, are capable of being heated to many times their original size without breaking. As a result of their exceptional flexibility, components can be shaped into the desired shape using specialized forming equipment that applies air pressure and/or tool movement.

Superplasticity Mechanism Segment Analysis

The microstructural segment in the superplastic alloys market is poised to garner largest revenue share of about 60% over the forecast period. Microstructural is considered to be the most significant process for the production of superplastic alloy since it could go through deformation at high temperatures. Hence, its application is also growing in the medical sector since it is required to molded in unique shapes and sizes. Further, it has also been rigorously used in manufacturing various consumer electronics which includes wearable devices, smartphones, headphones, and more since these devices need to carry low weight and durability.

Our in-depth analysis of the global superplastic alloys market includes the following segments:

|

Substrate Material |

|

|

Superplasticity Mechanism |

|

|

Superplastic Forming Method |

|

|

Application |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Superplastic Alloys Market - Regional Analysis

North American Market Insights

North America industry is expected to account for largest revenue share of 40% by 2035. The major element to influence the market growth in this region is the rising production of aircraft. According to predictions, there were a greater number of aircraft in the US in 2021 about 204,404 total aircraft were in the general aviation fleet. Additionally, the government in this region is spending heavily on the defense sector which is why the adoption of superplastic alloys is rising. Furthermore, the region is predicted to have a huge number of manufacturers in the aerospace sector which has further led to huge competition among them. As a result, these manufacturers are opting for superplastic alloy it is estimated to offer the most efficient quality to the aerospace.

European Market Insights

The Europe superplastic alloys market is also poised to have notable growth during the forecast period. This could be owing to rising government initiatives for the adoption of electric vehicle. By 2050, Europe intends to achieve its lofty objective of being climate-neutral. Hence, in the upcoming years, the European Commission is projected to announce numerous new legislative measures in an effort to meet this goal. By the end of this decade, the European Commission expects to see a minimum of about 29 million electric vehicles on the road, a significant increase from the over 2 million EVs that are already on European roads. Moreover, a large number of people have been observed supporting this decision of the EU government. Also, this support has been also observed from the defense industry. For instance, in order to supply power to the electric fleet vehicles of Front-Line Command, the Defence Support organization has opened the first of three hydrogen-fueled charging spots. Hence, this factor is also estimated to boost the demand for superplastic alloys market in this region.

Superplastic Alloys Market Players:

- ATI

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Arconic Corporation

- CRS Holdings, LLC.

- Haynes International, Inc.

- Materion Corporation

- Norsk Hydro ASA

- Precision Castparts Corp.

- Sandvik AB

- Thyssenkrupp AG

- TimkenSteel Corporation

Recent Developments

- On Tuesday, April 13, during Tom Dixon Studio's "24 hours in Milan" digital event, the novel and inventive chair was unveiled. The HYDRO Chair is made of recyclable aluminium and is intended to last a long time. It is also multipurpose and, most significantly, easy to recycle. Because it is made entirely of aluminium and has few parts, it will be simple to disassemble when its useful life as a chair comes to an end.

- Arconic Corporation has revealed the commercial availability of ARCONIC-THOR, an advanced titanium alloy intended for higher temperature applications in next-generation aircraft engines and related structures. Because the patented ARCONIC-THOR is almost 50% lighter than existing nickel-based superalloys, customers benefit from cost and fuel efficiency benefits, and Arconic is able to meet the expanding demand for cutting-edge aero engine and airframe materials.

- Report ID: 2680

- Published Date: Nov 19, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Superplastic Alloys Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.