Steel Powder Market Outlook:

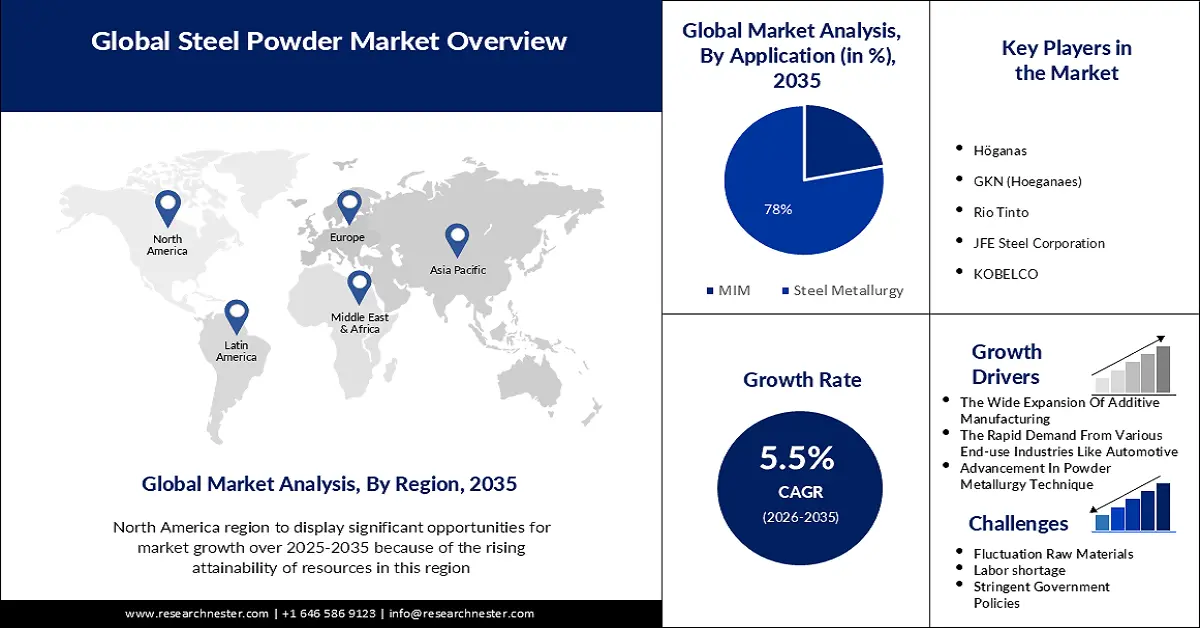

Steel Powder Market size was over USD 6.26 billion in 2025 and is anticipated to cross USD 10.69 billion by 2035, witnessing more than 5.5% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of steel powder is assessed at USD 6.57 billion.

The primary reason behind the growth of the market is the wide expansion of additive manufacturing. The commercial application in this event will be molds, e.g., for plastic injection. However, technologies that generate metal parts offer a straight dispute to metal casting (and other generation processes, too). As such, the latest X line 1000R laser metal sintering machine co-created by Concept Laser GmbH and Fraunhofer Institute for Laser Technology is a debate-changer. Its 630×400×500-mm create envelope is now reported as the biggest commercially accessible for laser melting.

Another reason that will propel the steel powder market by the end of 2036 is the rapid demand from various end-use industries like automotive. Today, the use of these highly precise components per automobile is increasing by between 6% and 7% per year. One of the factors for this powerful growth is the amalgamation of favorable cost and the properties of the components, both acknowledging intricate shape, accuracy and suitable physical properties. Low cost is given by the comfort with which the PM technique is machine-driven. The intricate shape is given by the domestic contour of the die and the profile of the other equipment members. Cutting, drilling turning, and other expensive forming operations can be eradicated. This not only helps to lower costs but also outcomes in essentially total eradication of waste. The PM technique presents great resilience also in providing custom-made component properties. The fact that the component is composed of a compilation of small particles of iron and other metals or elements, gives an additional degree of liberty for the materials engineer.