Self-healing Polymers Market Outlook:

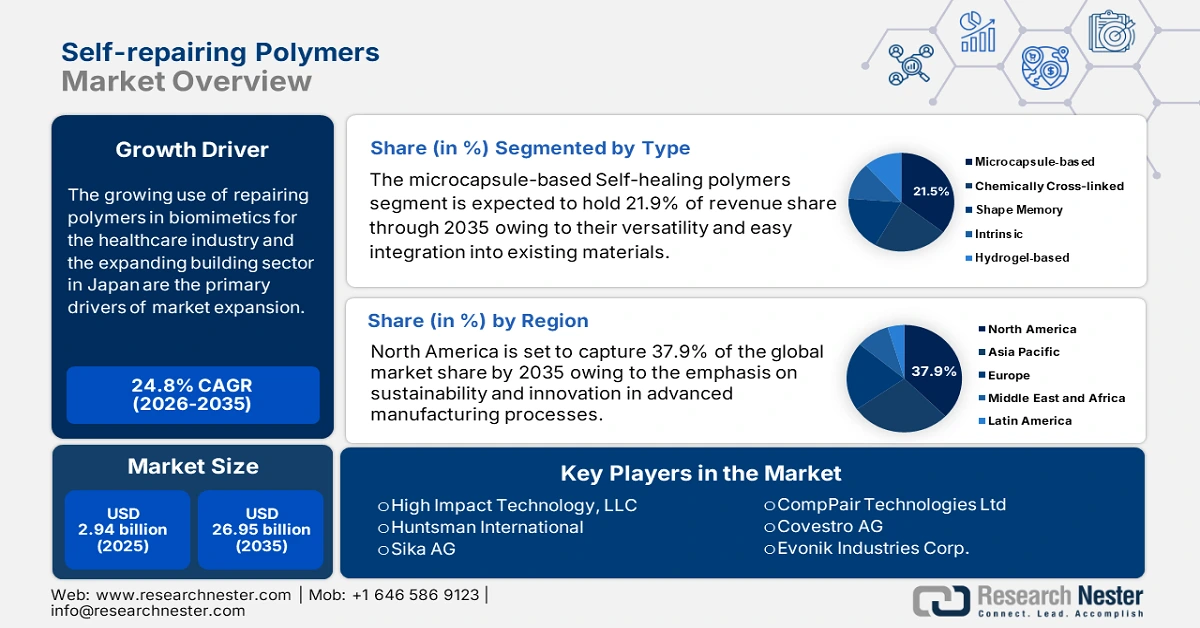

Self-healing Polymers Market size was valued at USD 2.94 billion in 2025 and is expected to reach USD 26.95 billion by 2035, expanding at around 24.8% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of self-healing polymers is assessed at USD 3.6 billion.

The self-healing polymers market is rapidly expanding due to rising public and private infrastructure construction projects across the globe, especially in developing economies Government programs including, the Make in India campaign make obtaining the raw materials needed for the construction industry easier, further supporting domestic manufacturing processes. The adoption of self-healing polymers is rapidly increasing in modern constructions due to its durability and strength and several companies are developing innovative products. In November 2022, Worcester Polytechnic Institute researchers developed a self-healing concrete that repairs cracks using carbon dioxide. The team chose to incorporate carbonic anhydrase (CA), an enzyme found in red blood cells, into the concrete mix. The CA reacts with carbon dioxide to form calcium carbonate crystals and seals the gaps.

Key Self-healing Polymers Market Insights Summary:

Regional Highlights:

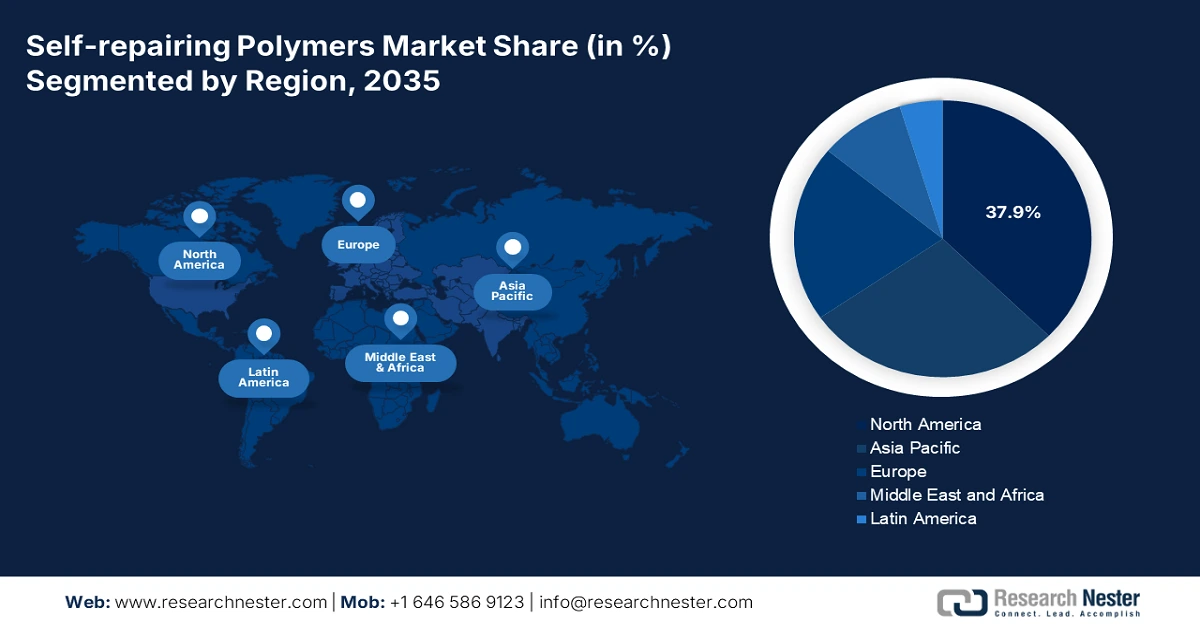

- North America commands a 37.9% share in the Self-healing Polymers Market, with sustainability focus and strong R&D driving innovation and growth through 2026–2035.

- The Asia Pacific self-healing polymers market is expected to see stable growth through 2035, fueled by urbanization and adoption in electronics and construction.

Segment Insights:

- Microcapsule-based Self-healing Polymers segment are expected to grow at 21.5% by 2035, fueled by their ease of integration, versatility, and self-repair capabilities.

- The Automotive segment of the Self-healing Polymers Market is expected to capture over 29.5% share by 2035, fueled by the need for durable materials that reduce maintenance and extend vehicle lifespan.

Key Growth Trends:

- Growing use in consumer electronics

- Ongoing development in nanotechnology and material science

Major Challenges:

- Intricate manufacturing procedure

- High expenses of manufacture

- Key Players: BASF SE, CompPair Technologies Ltd, Covestro AG, Evonik Industries Corp., High Impact Technology, LLC, Huntsman International, Sika AG.

Global Self-healing Polymers Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 2.94 billion

- 2026 Market Size: USD 3.6 billion

- Projected Market Size: USD 26.95 billion by 2035

- Growth Forecasts: 24.8% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: North America (37.9% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: United States, China, Germany, Japan, United Kingdom

- Emerging Countries: China, India, South Korea, Brazil, Mexico

Last updated on : 14 August, 2025

Self-healing Polymers Market Growth Drivers and Challenges:

Growth Drivers

- Growing use in consumer electronics: The self-healing polymers market is growing due to the expanding use of self-healing polymers in consumer electronics. As the need for lightweight, flexible, and long-lasting materials grows, producers are searching for ways to improve product life cycles. For gadgets such as smartphones, wearables, and tablets, self-healing polymers provide the capacity to fix tiny flaws like scratches or cracks. This technology makes electrical devices more valuable and improves the customer experience. Businesses that successfully incorporate self-healing polymers into their production procedures might reach a rising self-healing polymers market of tech-savvy and ecologically sensitive customers. For example, in July 2024, a team of researchers from the University of California, Riverside developed an electrically activated transparent, extremely stretchy, self-healing material. As a result, it works particularly well for enhancing the functionality of robotics, smartphones, and other electronic gadgets.

- Ongoing development in nanotechnology and material science: Companies and research organizations are making significant investments to strengthen polymer structures to increase their capacity and enhance self-repair damage. These cutting-edge polymers are being incorporated into products by the construction, automotive, and aerospace industries, which stand to gain from lower maintenance costs and increased safety as a result of longer material lifespans.

- The trend toward sustainability: Growing environmental concerns and the need for eco-friendly products are key factors expected to drive self-healing polymers market growth during the forecast period. To lessen their carbon impact businesses are putting more effort into creating self-healing polymers with bio-based or renewable resources. This is in line with the global trend toward greener options, especially in sectors where environmental effects and durability are crucial. Innovations in biodegradable self-healing polymers are gaining pace as manufacturers and consumers prioritize sustainability, supporting self-healing polymers market expansion. In August 2023, scientists from the University of Konstanz announced the development of a self-healing mineral plastic that can be shaped to fit the required product before it hardens and can be restored to its original state and reshaped anytime by adding water.

Challenges

- Intricate manufacturing procedure: One significant problem is the intricate manufacturing procedure, which makes large-scale production of these materials challenging. This intricacy may restrict the supply of self-healing polymers and raise production costs. There are also technical obstacles to overcome. One major challenge is making sure that these polymers can efficiently repair themselves in a variety of scenarios, including those with varying temperatures and stress levels. These technological issues may have an impact on the materials' performance and dependability, which could reduce their appeal to customers.

- High expenses of manufacture:Self-healing polymers' high production costs continue to be a significant barrier to self-healing polymers market expansion. These polymers are more costly than their conventional counterparts due to the sophisticated technologies and specialized materials needed for production. Their use is restricted by this cost aspect, particularly in businesses where prices are crucial. Budgetary restrictions make it difficult for small and medium-sized businesses in particular to use these materials for their goods.

Self-healing Polymers Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

24.8% |

|

Base Year Market Size (2025) |

USD 2.94 billion |

|

Forecast Year Market Size (2035) |

USD 26.95 billion |

|

Regional Scope |

|

Self-healing Polymers Market Segmentation:

Type (Microcapsule-based Self-healing Polymers, Chemically Cross-linked Self-healing Polymers, Shape Memory Polymers, Intrinsic Self-healing Polymers, Hydrogel-based Self-healing Polymers)

Microcapsule-based self-healing polymers market is projected to hold 21.5% revenue share by 2035. Microcapsule-based versions are the industry leaders due to their versatility and easy integration into existing materials. These polymers have microcapsules of healing chemicals inside their matrix that, when broken, activate and repair the material automatically. In sectors including electronics, construction, and automotive, this technology has gained extensive usage due to its potential to increase material lifespan and reliability without the need for external interventions. Despite the increasing popularity of chemically cross-linked polymers that rely on dynamic covalent connections for self-repair due to their endurance, the market still favors the more adaptable microcapsule-based systems.

End use (Automotive, Electronics, Healthcare, Construction, Others)

By 2035, automotive segment is set to capture over 29.5% self-healing polymers market share. The primary force behind this shift is the automotive industry's need for strong, long-lasting materials to lower service costs and lengthen vehicle lifespan. Automakers are increasingly employing self-healing polymers for a range of applications, from external coatings to structural parts, to boost durability, lower maintenance costs, and extend vehicle lifespans. Surface coatings are one of the most obvious uses for self-repairing materials, especially in the automotive sector. Tiny chips or scratches in paint can act as an entry point, causing widespread corrosion. Paint and other coating materials shield metal from oxygen in the air and water, which causes oxidation and rust. Therefore, self-repairing surface coatings would greatly extend the operational lifespan of structural components and shield them from oxidation.

Our in-depth analysis of the global market includes the following segments:

|

Type |

|

|

End use |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Self-healing Polymers Market Regional Analysis:

North America Market Analysis

North America industry is set to hold largest revenue share of 37.9% by 2035. The growing emphasis on sustainability and innovation in advanced manufacturing processes is propelling the market in North America. These materials are being used in the designs of industries such as automotive, aerospace, and defense to lower lifecycle costs and increase product life. Research and commercialization of self-healing polymers are being further propelled by the region's established R&D capabilities and government support for eco-friendly materials, especially as businesses look to satisfy consumer demand for sustainable products and more stringent environmental regulations.

The growing application of self-healing polymers in high-tech sectors like electronics and healthcare is driving the self-healing polymers market in the U.S. The need for self-healing polymers is rising as a result of the need for tougher and more resilient materials in next-generation consumer electronics, especially wearables and smartphones. Furthermore, due to these polymers prolong the lifespan of vital components through self-repair mechanisms, the U.S. healthcare industry is paying closer attention to their use in implants and medical devices to improve patient safety and lower medical expenses.

One of the main factors driving the Canada self-healing polymers market is the growing demand for advanced materials in the aerospace and infrastructure industries. Self-healing polymers are used in high-stress applications including pipelines, bridges, and aviation components owing to their remarkable adhesion, chemical resistance, and structural integrity. In addition, rising investments in developing advanced self-healing polymers and government efforts to support the adoption of these polymers are expected to drive market growth in Canada.

Asia Pacific Market Analysis

Asia Pacific is expected to experience a stable CAGR during the forecast period owing to swift urbanization and industrialization in China, South Korea, Japan, and India. The rising adoption of self-healing polymers in electronics, automobiles, and building and construction for repairing minor damages and cracks is another factor expected to drive self-healing polymers market growth in Asia Pacific.

China’s rapid urbanization and expanding construction sector along with government initiatives, including, Made in China 2025 are encouraging the integration of advanced materials. In addition, the country’s focus on smart technologies and sustainable materials is propelling the usage of self-healing polymers in industries where innovation and cost-effectiveness are essential, such as electronics, construction, and healthcare.

The construction of both public and private infrastructure in India is driving the growth of the self-healing polymer industry. The self-healing polymer has several uses in infrastructure that would help the building industry owing to its durability and strength. Additionally, the expanding use of composites, CMCs, and polymer-based building materials will propel the revenue of the self-healing polymers market. For instance, in July 2023, for photovoltaic applications, researchers at the Indian Institute of Technology (IIT Bhilai) created a novel self-healing polymeric coating material that exhibits the capacity to mend cracks on its own and provides an affordable and easily accessible alternative to self-healing coating materials.

Key Self-healing Polymers Market Players:

- Aditya Birla Group

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- BASF SE

- CompPair Technologies Ltd

- Covestro AG

- Evonik Industries Corp.

- High Impact Technology, LLC

- Huntsman International

- Sika AG

A competitive landscape with many major competitors propelling innovation and market expansion characterizes the industry. To improve the performance, affordability, and sustainability of their goods, major companies in this industry are making significant investments in research and development. One of the top manufacturers of self-healing polymers, BASF SE creates polymers with sophisticated self-healing qualities appropriate for a variety of uses, such as electronics, construction, and automobiles.

Here are some leading players in the self-healing polymers market:

Recent Developments

- In June 2024, a researcher from Australia's Swinburne University of Technology developed a novel kind of carbon fiber reinforced polymer composites that will allow submarines in the future to recognize and repair microcracks on their own. This cutting-edge substance is made to behave similarly to living things, sensing, reacting, and adjusting to stressors and flaws instantly.

- In August 2022, BASF introduced a new paint protection film made of thermoplastic polyurethane (TPU), which can mend itself and protect car surfaces from dings and scratches. Minor dings can be automatically fixed by this cutting-edge TPU film, preserving the vehicle's durability and visual appeal.

- Report ID: 6626

- Published Date: Aug 14, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Self-healing Polymers Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.