Rice Husk Ash Market Outlook:

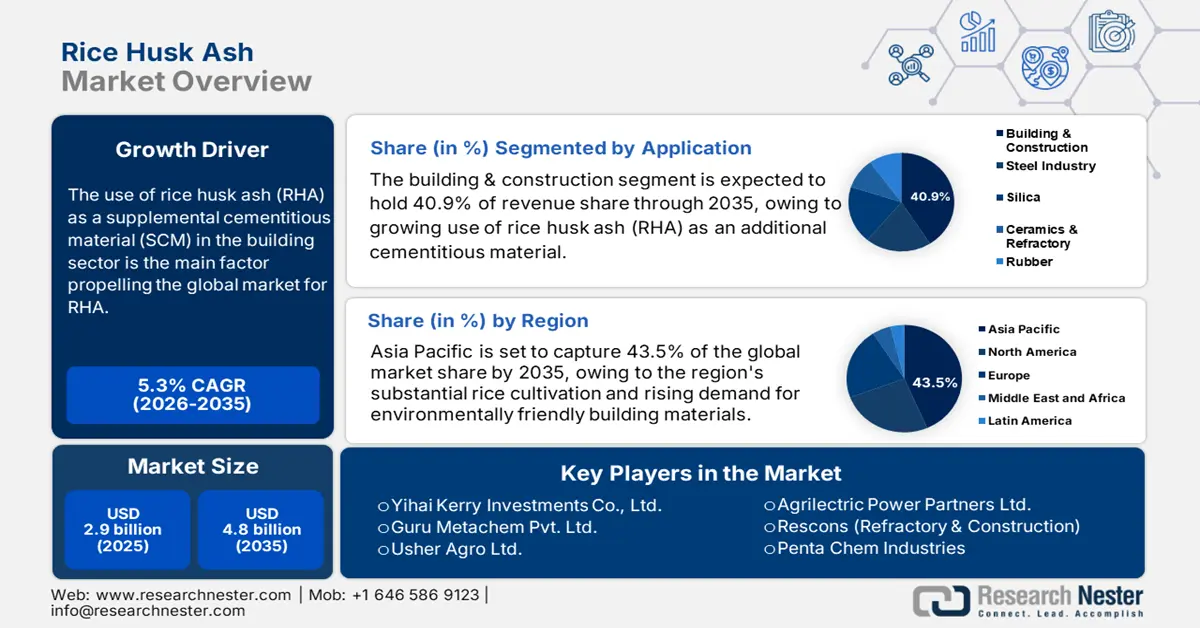

Rice Husk Ash Market size was valued at USD 2.9 billion in 2025 and is projected to reach USD 4.8 billion by the end of 2035, rising at a CAGR of 5.3% during the forecast period from 2026 to 2035. In 2026, the industry size of rice husk ash is estimated at USD 3.2 billion.

The rice husk ash market is expected to expand notably during the projected period, primarily driven by the use of rice husk ash (RHA) as a supplemental cementitious material (SCM) in the building sector. Because of its high silica concentration, RHA is a sustainable substitute for conventional cement in concrete, increasing its strength and longevity. The implementation of RHA has also been accelerated by government programs supporting sustainable construction methods. To illustrate its potential for infrastructure projects, the U.S. Department of Transportation, for example, has investigated the use of RHA in flowable fill concrete mix materials.

Moreover, the consistent supply of rice husks, a byproduct of rice milling, which in turn relies on the global rice production volume, is another factor driving rice husk ash market growth. The Food and Agriculture Organization (FAO) reports that the world production of rice on a milled basis has attained a production of about 517.1 million tons in 2021, a slight improvement of about 0.7% over the last year. Additionally, the FAO forecasts a turnaround with the world rice production projected to be at 543 million tonnes in the 2024/25 season due to good growing conditions, especially in India, Cambodia, and Myanmar. This continuous large amount of rice production guarantees a constant supply of rice husks, which may be burnt or refined to produce rice husk ash, which is a very important raw material in several manufacturing activities, including cement replacement and stabilization of soil.

The production of rice is inextricably related to the RHA supply chain, as rice husks are a by-product of milling. In India, for instance, almost 120 million tons of rice husk are produced each year. This plentiful supply helps RHA increase its manufacturing capabilities. However, consistent RHA quality is hampered by the absence of standardized processing techniques and quality control procedures. However, the global mobility of rice and its byproducts indicates a possibility for RHA trade, particularly in places with substantial rice production, even though detailed import/export statistics on RHA are scarce. Enhancing RHA processing methods and broadening its uses require research and development expenditures.

The U.S. Bureau of Labor Statistics has a PPI of Processed foods and Feeds Milled Rice (Including second heads, screenings, brewers, Bran, Sharps, Rice Flour, and Byproducts) in series WPU 02130201. This index, as of August 2025, was 163.095 (June 1984=100). In addition, the industry sources reveal that the prices for RHA are dependent on purity and usage. For example, in Panipat, India, RHA is estimated to cost 1000 rupees per 60-foot container, whereas in Ahmedabad, Gujarat, it costs 15 to 50 rupees per kilogram, depending on purity and form. Such prices are affected by the content of silica, the particle size, and the purpose for which they are to be used in high-performance concrete and ceramics.