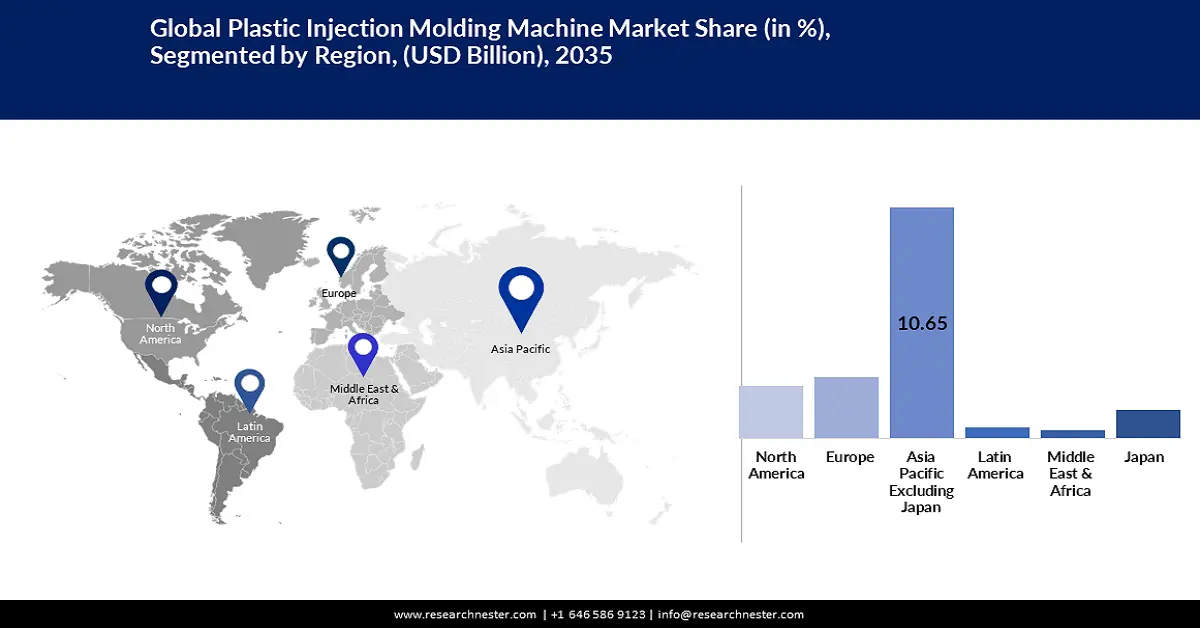

Plastic Injection Molding Machine Market Regional Analysis:

Asia Pacific Market Insights

Asia Pacific plastic injection molding machine market is predicted to account for revenue share of around 59.4% by 2035, owing to industrialization, consumer demand, and manufacturing support from the government. In January 2025, YIZUMI and KUKA Robotics formed a strategic partnership for the advancement of smart manufacturing and robotic automation. The partnership will integrate artificial intelligence in controlling the machinery with the use of flexible production platforms. Such partnerships are likely to mark a new era of intelligent, high-precision molding machines designed for mass production across Asia.

The plastic injection molding machine market in China remains on an upward trajectory and is in sync with the country’s manufacturing recovery. Industrial production increased by 6.7% YoY in April 2024, showing the beginning of production recovery. YIZUMI, with the support of KUKA’s automation solutions, is strengthening China’s position as a leader in advanced molding equipment. The electronics industry and electric vehicle segment of the country are driving the need for advanced, high-speed molding systems with the capability to manage complex part shapes and challenging cycle time specifications.

India is poised to become a significant molding hub with the help of international collaborations and internal changes. In December 2024, Electronica Plastic Machines signed a Memorandum of Understanding with ENGEL Group to jointly work on designing suitable molding technologies for the Indian plastic injection molding machine market. ENGEL’s technology transfer and capital investment focus on enhancing the overall manufacturing capacity of India. Such collaboration means an increased focus on precision molding, first-line autonomy, and export-oriented competitiveness, the dynamics that are likely to propel India plastic injection molding machine industry growth.

North America Market Insights

North America region is projected to register substantial growth through 2035, due to the growth of domestic manufacturing, the return of supply chains, and increasing automation. In January 2025, Markdom, began a new production facility worth USD 19 million in the U.S., which improved regionalization and local capacity. The investment will help to locate high-output molding closer to its end-use plastic injection molding machine markets and reduce reliance on imports. These investments show how molding is set to benefit from capacity expansion, infrastructure improvement, and qualified workforce availability in North America.

The U.S. remains a hub of technological advancement in high-performance molding solutions through the support of regulatory frameworks and digital technology. In March 2024, Stork IMM increased its service capacity in North America to provide more support after the sales of its machines and to ensure the machines’ efficiency. This reflects an increase in the need for application-specific performance support in high-speed molding systems, which the facility enhances by providing parts and technical support. This regional strategy confirms the transition of the U.S. plastic injection molding machine market from a product-based market to a market that focuses on long-term equipment partnerships and performance-based services.

The plastic injection molding machine industry in Canada is experiencing expansion due to the implementation of sustainability standards and the integration of new technologies. Businesses are focusing on energy-saving equipment and technologies and the use of robots to sustain themselves in the international plastic injection molding machine market. Measures by regional governments to promote the adoption of clean technology add to the pressure on molding operations to transition to electric or hybrid solutions. Cross-border partnerships and logistics integration are making Canada a strategic partner for high-volume precision manufacturing throughout North America.