Metal and Ceramic Injection Molding Market Outlook:

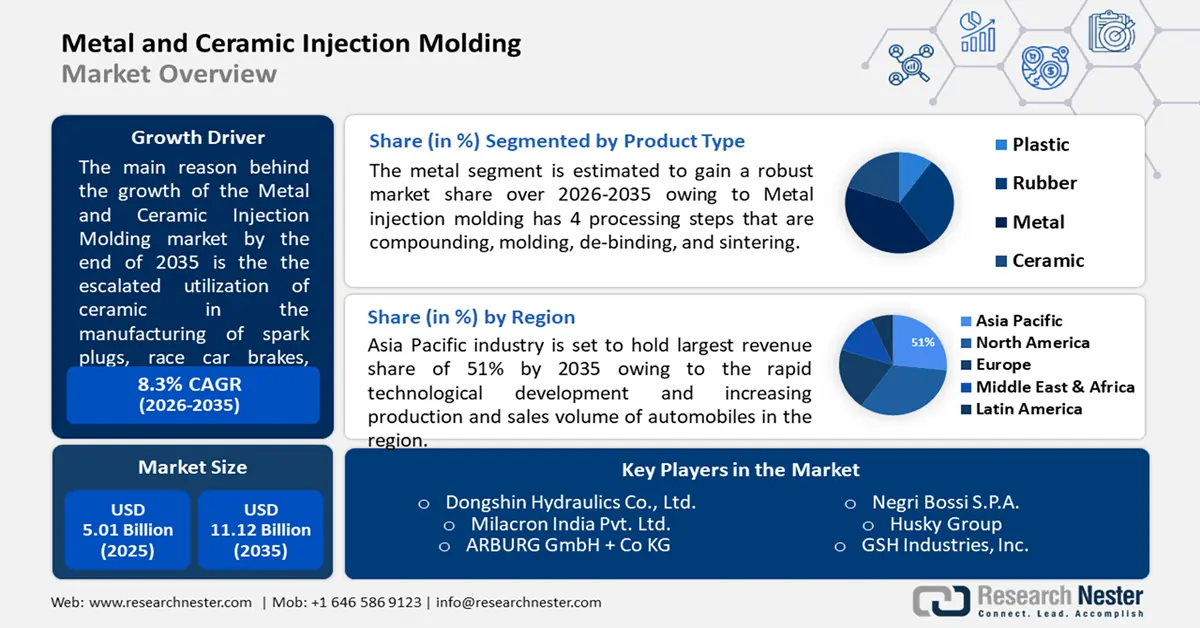

Metal and Ceramic Injection Molding Market size was over USD 5.01 Billion in 2025 and is anticipated to cross USD 11.12 Billion by 2035, witnessing more than 8.3% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of metal and ceramic injection molding is assessed at USD 5.38 Billion.

The growth of the market can be attributed to the escalated utilization of ceramic in the manufacturing of spark plugs, race car brakes, skis, body armor, cooktops, space shuttle tiles, artificial joints, and others. Ceramics are utilized to make this structure since this type of molding technology is highly suitable for complex structures and high strength. The higher production and sales volume of skiing equipment is estimated to propel the market growth over the forecast period. For instance, in 2019, around 650,000 snowboards were sold out across the globe while nearly 3 million alpine skis were purchased by people globally. The sales volume of cross-country skis was estimated to be around 1 million in a similar year.

Global metal and ceramic injection molding market trends such as the growing inclination of the global population towards skiing triggering the demand for skiing equipment and expansion in the chemical industry with robust demand for metal and ceramic injection molding are expected to hike the market growth over the forecast period. For instance, it is projected that approximately 350 million people visit ski resorts every year. Furthermore, ceramic is used widely in the automotive industry to make lightweight vehicles, which is expanding significantly across the globe. According to the U.S. Department of Energy, about a 10% reduction in vehicle weight can result in a 6%-8% fuel economy improvement. Hence, this is estimated to be a significant factor to drive the growth of the global metal and ceramic injection molding market.

Key Metal and Ceramic Injection Molding Market Insights Summary:

Regional Highlights:

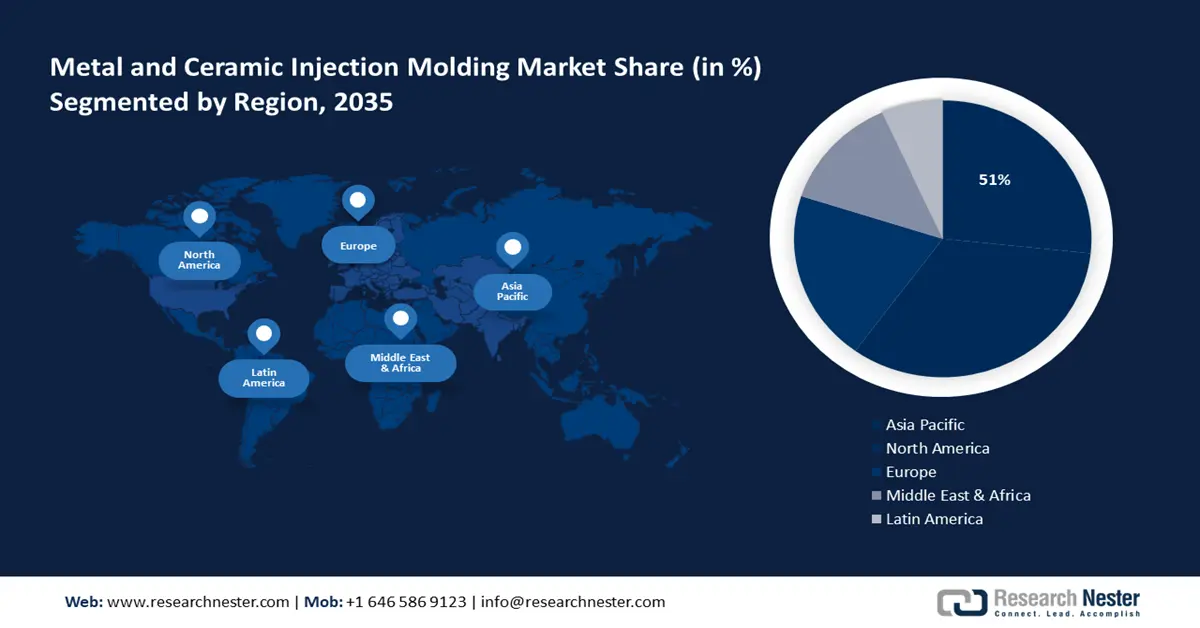

- Asia Pacific metal and ceramic injection molding market will secure around 51% share by 2035, driven by robust automotive industry and high automobile production.

Segment Insights:

- The metal segment in the metal and ceramic injection molding market is forecasted to capture a significant share by 2035, driven by the use of metal injection molding in producing complex parts with tight tolerances.

- The healthcare segment in the metal and ceramic injection molding market is anticipated to achieve the largest share by 2035, attributed to a large patient pool requiring treatment and increased use of injection molding in medical devices.

Key Growth Trends:

- Growing Manufacturing of Automobiles Across the Globe

- Increasing Expansion Rate of Construction Industry

Major Challenges:

- Higher Machine Tooling Cost

- Design Restrictions

Key Players: Sumitomo Heavy Industries, Ltd., Chen Hsong Holdings Limited, Japan Steel Works, Ltd., Nissei Plastic Industrial Co., LTD., Negri Bossi S.P.A., Husky Group, GSH Industries, Inc., Dongshin Hydraulics Co., Ltd., Milacron India Pvt. Ltd., ARBURG GmbH + Co KG.

Global Metal and Ceramic Injection Molding Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 5.01 Billion

- 2026 Market Size: USD 5.38 Billion

- Projected Market Size: USD 11.12 Billion by 2035

- Growth Forecasts: 8.3% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (51% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: China, United States, Germany, Japan, South Korea

- Emerging Countries: China, India, Brazil, Mexico, South Korea

Last updated on : 10 September, 2025

Metal and Ceramic Injection Molding Market Growth Drivers and Challenges:

Growth Drivers

-

Growing Manufacturing of Automobiles Across the Globe – as of 2021, nearly 65 million units of automobiles were sold out worldwide. In 2021-22, around 3 million passenger vehicles, 0.7 million commercial vehicles, 0.2 million three-wheelers, and nearly 10 million two-wheelers were sold out across the globe.

The injection molding method is used significantly and widely in the automotive sector in the production process to make mold cavities by injecting molten plastic materials this process is known as screw precession. There are several stages of injection molding such as injection, clamping, colling, dwelling, mold opening, and others. The automotive sector is growing rapidly across the world. Hence, this is anticipated to be an important factor to drive market growth during the forecast period. -

Increasing Expansion Rate of Construction Industry – According to estimates, by the end of 2025, the construction industry in India is expected to reach a total value of USD 1.3 trillion. The injection molding used in construction has various advantages such as specific size, competitive costing, enhanced insulation, excellent finish, sustainable solutions, and others.

-

Rising Government Support to Expand the Chemical Industry – Within the Union Budget 2022-23, the Indian government allocated approximately USD 27 million to the Department of Chemicals and Petrochemicals. Moreover, the global chemical industry garnered revenue of nearly USD 4 trillion around the world in the year 2021.

-

Growing Demand for Electric and Non-Electric Vehicles – In hybrid and electronic vehicles, injection molding is increasingly used. It was observed that nearly 13,34,000 electric vehicles are in use in India, compared to approximately 27,80,50,000 non-electric vehicles.

-

Higher Demand in Firearm Industry – it was estimated that around 9 million guns are manufactured across the globe every year in the United States while another estimate showed that the U.S. firearm industry is a major part of the national economy contributing around USD 50 billion.

Challenges

- Higher Machine Tooling Cost - Since the raw material used in the metal and ceramic injection molding is high, it also spikes the overall cost of molded products. Furthermore, three-dimensional product manufacturing is restricted which is also estimated to hamper the market growth during the forecast period.

- Design Restrictions

- Lack of Availability of Expert Professionals

Metal and Ceramic Injection Molding Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

8.3% |

|

Base Year Market Size (2025) |

USD 5.01 Billion |

|

Forecast Year Market Size (2035) |

USD 11.12 Billion |

|

Regional Scope |

|

Metal and Ceramic Injection Molding Market Segmentation:

End-user Segment Analysis

The global metal and ceramic injection molding market is segmented and analyzed for demand and supply by end users into automotive, packaging, consumer goods, electronics, and healthcare. Out of these segments, the healthcare segment is estimated to gain the largest market share by the year 2035. The growth of the segment can be attributed to the existence of a huge patient pool that requires treatment in hospital facilities and the higher utilization of metal and ceramic injection molding in the manufacturing of sensors, implants & dental equipment, tubes, micro-optics, and others. Higher demand for dental implants can be observed across the globe. For instance, it was estimated that around 32 million Americans are in the need of implants since they lack at least one tooth. Moreover, rising healthcare expenditure per capita on healthcare is also estimated to add to the growth of this segment in the market. As per The World Bank, the current health expenditure of the year 2019, accounted for 9.83% of the global GDP.

Product Type Segment Analysis

The global metal and ceramic injection molding market is also segmented and analyzed for demand and supply by product type into plastic, rubber, metal, and ceramic. Amongst these four segments, the metal segment is expected to garner a significant share in the year 2035. Metal injection molding machine is used to make complex and simple parts that contain tight tolerances. Metal injection molding has 4 processing steps that are compounding, molding, de-binding, and sintering. In this process, many types of alloys are used such as copper, titanium, nickel, tungsten, and cobalt alloys along with high-speed and stainless steel.

Our in-depth analysis of the global market includes the following segments:

|

By Product Type |

|

|

By End User |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Metal and Ceramic Injection Molding Market Regional Analysis:

APAC Market Statistics

Asia Pacific industry is set to hold largest revenue share of 51% by 2035. Asia has the world’s most robust automotive industry where the sales, production, and export, of automobiles, are comparatively high. Since metal and ceramic molding is heavily used in the manufacturing of automotive parts, therefore, higher production of automobiles is expected to expand the market size over the forecast period. For instance, in China alone, around 20 million passenger cars were produced in 2021 while in Sought east Asia, around 2 million automobiles were produced, additionally, in Japan, more than 6 million passenger cars were manufactured. Furthermore, the higher requirement for firearms in the defense system of the region is anticipated to hike firearm production which is expected to spike the demand for metal and ceramic injection molding in the projected timeframe. Therefore, all the factors are anticipated to influence the regional market growth positively over the forecast period.

North American Market Forecast

Additionally, the global metal and ceramic injection molding market is further expected to witness lucrative growth opportunities in the North American region. The growth of the market can be attributed majorly to the rapid technological development and increasing production and sales volume of automobiles in the region. In the United States, the inclination of the population is observed to rise toward luxury cars which are further supported by the spiking personal income and presence of the excellent highways and roads. As of 2022, over 75 percent of the U.S. population reported having access to their car, with an additional 19 percent having access to a company or family car. Moreover, the surge in firearm production owing to the significant expansion in the firearm industry in the region and change in the government initiatives to keep firearms is also anticipated to hike the market growth over the forecast period. For instance, in the United States, approximately 12 million firearms were manufactured in 2021.

Metal and Ceramic Injection Molding Market Players:

- Sumitomo Heavy Industries, Ltd.

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Chen Hsong Holdings Limited

- Japan Steel Works, Ltd.

- Nissei Plastic Industrial Co., LTD.

- Negri Bossi S.P.A.

- Husky Group

- GSH Industries, Inc.

- Dongshin Hydraulics Co., Ltd.

- Milacron India Pvt. Ltd.

- ARBURG GmbH + Co KG

Recent Developments

-

Sumitomo Heavy Industries, Ltd. – Sumitomo Heavy Industries, Ltd released the all-electric small injection molding machine SE30EV-A that enables speedy set-up, precise, stability, production management, and reduction of environmental loads. The special features such as an advanced touch panel controller and low vibration greatly lead to improvement in the production field.

-

Chen Hsong Holdings Limited to provide the First New Batch of MK6 & SMTP Injection Molding Machines at its BYD factory for a celebration event. BYD is known to be the largest new energy vehicle manufacturer in China.

- Report ID: 4565

- Published Date: Sep 10, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Metal and Ceramic Injection Molding Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.