IO-Link Industry - Regional Scope

Europe Market Insights

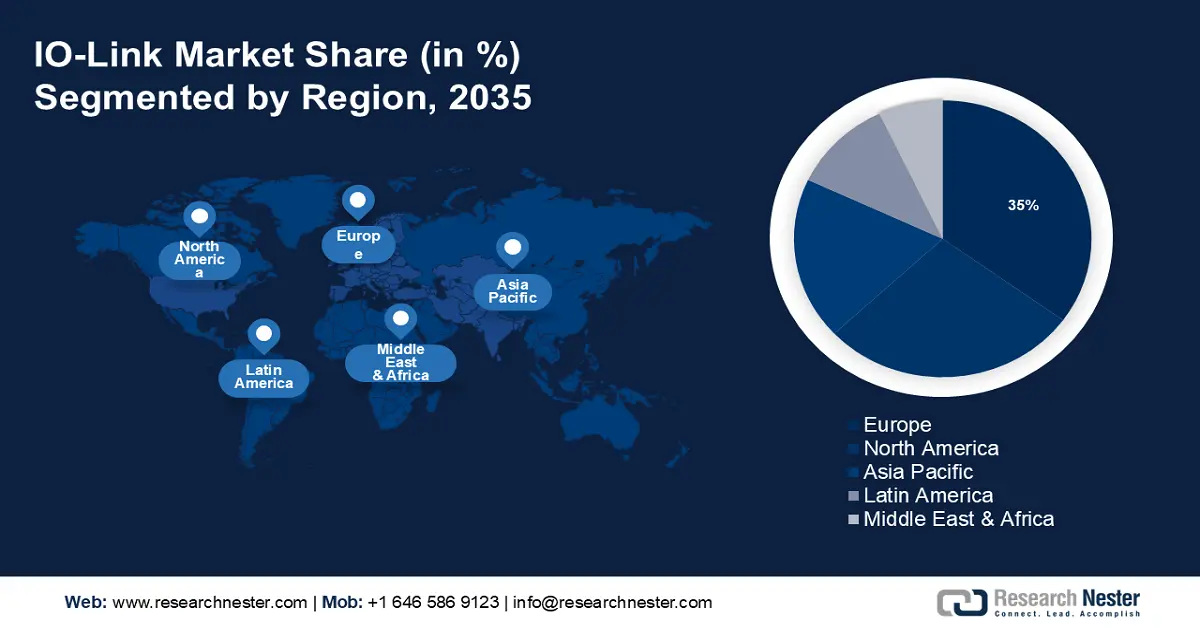

The IO-link market in Europe is expected to account for the largest revenue share of about 35% during the forecast period, owing to the robust manufacturing sector. The manufacturing industries are leveraging Industry 4.0 principles, resulting in simultaneous growth in efficient and interoperable automation solutions. IO-Link technology is essential for enabling shorter machine downtimes, so industries including automotive, food & beverage, and chemicals find it highly desirable for their operations across the region.

The governments are investing in digital transformation initiatives to enhance industrial market positions. The adoption of technologies such as IO-Link is increasing due to initiatives such as the German Industry 4.0 Initiative and European Digital Innovation Hubs, which focus on promoting automation, connectivity, and smart manufacturing. Europe market is experiencing rapid expansion in the IO-link field owing to requirements for smarter factories, improved cybersecurity, as well as Industrial IoT implementation.

The IO-link sales in the U.K. are all set to register a healthy growth in the forthcoming years, owing to the requirements for productivity improvement, reduced operational costs, and market competitiveness. There is an increasing demand for IO-Link technology in the market, as automation solutions implement real-time data processing and machine-to-machine communication procedures. IO-Link establishes smooth communication between sensors, actuators, and control systems, driving manufacturers to adopt efficient automation processes, resulting in market expansion and cost savings.

The increasing demand for predictive maintenance tools for automotive, aerospace, and energy operations is contributing to the overall market growth. The monitoring capabilities and diagnostics functions of IO-Link are preventing machine breakdowns and minimizing unexpected equipment stoppages. In addition, the industries are aimed at lowering maintenance expenses while extending operational duration, further fostering the market growth.

North America Market Insights

The North America IO-link market is expected to hold second second-largest revenue share of about 28% during the forecast period. The industrial evolution and the Industrial IoT are rapidly increasing across the region. The rise of IO-link is essential for modern industries as they require improved operational efficiency and cost reduction, along with digital technology integration. The technology's sensor and actuator to control system communications fit perfectly into modern requirements of data analytics and machine learning techniques. Real-time monitoring requirements and rising automation trends are driving manufacturers to adopt IO-Link technology.

Government support through funding initiatives is promoting the widespread use of IO-link technology through advancements in manufacturing innovation. The U.S. Department of Energy is supporting industrial growth across multiple business sectors through initiatives that provide grants and subsidies for smart sensors and automation adoption.

The U.S. IO-link sales are exhibiting steady growth during the forecast period. There is a rising focus on sustainability and energy efficiency across different industrial sectors in the country. Organizations are using technology tools to detect energy usage while minimizing waste and maximizing their resource management capabilities. The IO-link provides real-time data from sensors and actuators, which supports permanent process energy consumption supervision. This data collection method enables energy cost reductions and regulatory compliance, as well as sustainable practices, boosting the IO-link market expansion.

Robotics and automation technologies are experiencing rapid growth in the market, fueling the automotive, electronics production, and supply chain operations. The key function of IO-Link in robotic systems consists of delivering improved interoperability as well as increased flexibility to advance robotic technologies. Companies that choose automated solutions to boost precision levels and efficiency skills require reliable and scalable connectivity, which is provided through IO-link as their operations expand.