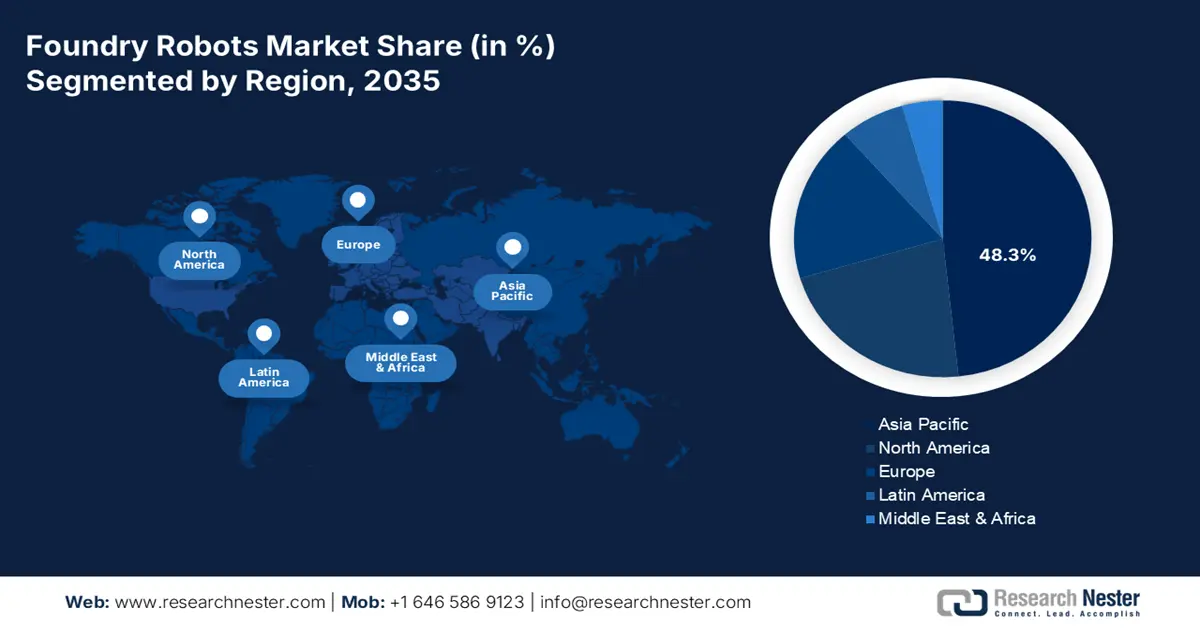

Foundry Robots Market - Regional Analysis

APAC Market Insights

Asia Pacific in the foundry robots market is anticipated to account for the largest share of 48.3% by the end of 2035. The market’s upliftment in the region is effectively attributed to the strong extension of robust automotive and manufacturing industries is one of the notable drivers driving the foundry robots sales. Additionally, an increase in the die casting volume demand, along with substantial government ICT investments, is also catering to the foundry robots trade. According to an article published by the ABD Organization in 2025, the international expenditure on digitalized transformation is predicted to reach USD 3.9 trillion by the end of 2027, with the region accounting for over 33% of the share, which is driving the market’s growth.

The foundry robots market in China is projected to increase at a high pace, owing to the massive manufacturing base and aggressive smart factory policies. The digital shift has led to the swift integration of AI and IoT in robotics. As per the March 2025 IFR Organization article, the country’s National Development and Reform Commission has notified a long-lasting fund on next-generation innovation, AI, and robotics, amounting to 1 trillion yuan (USD 138 billion) for more than 20 years. The objective is to continue the country’s technology-based success in manufacturing, thereby boosting the market’s development.

The foundry robots market in India is also gaining increased traction, owing to the provision of generous support from governmental strategies, such as the Make in India campaign, along with PLI schemes for advanced chemistry cell and automotive batteries. These administrative policies are readily encouraging regional manufacturing, which has resulted in an upsurge in investments in automated foundries. For instance, the Department of Heavy Industry has provided support for adopting innovative manufacturing technologies to optimize the competitiveness of the capital goods sector. Additionally, the supply chain aspect of industrial robots is also fueling the market’s demand in the country, as well as in the overall region.

Industrial Robots 2023 Export and Import in the Asia Pacific

|

Countries |

Export |

Import |

|

Japan |

USD 279 million |

USD 30.2 million |

|

China |

USD 183 million |

USD 57.8 million |

|

South Korea |

USD 51.2 million |

USD 28.4 million |

|

India |

USD 1.5 million |

USD 9.3 million |

|

Malaysia |

USD 2.8 million |

USD 8.7 million |

|

Singapore |

USD 3.0 million |

USD 20.4 million |

|

Thailand |

USD 1.8 million |

USD 20.3 million |

Source: OEC

Europe Market Insights

Europe in the foundry robots market is expected to emerge as the fastest-growing region during the projected period. The market’s exposure in the region is driven by the presence of regulatory ESG as well as automotive electrification mandates to uplift the sales of foundry robots. In addition, the automation of high-precision casting in automotive and aerospace foundries is further fueling the application of foundry robots. As per an article published by NLM in March 2023, 25% of large-scale enterprises in the region utilize robots, along with 12% medium-scale enterprises, and 5% of small-scale enterprises. Therefore, this increased adoption of robots in regional workplaces is rapidly bolstering the market’s growth.

Germany is leading the sales of the foundry robots market, and the country’s dominance in the automotive and industrial machinery sectors is propelling the demand for foundry robots. The early adoption of Industry 4.0. and strong presence of tech-savvy consumers is also increasing the adoption of advanced foundry robots. As per the June 2024 OECD data report, the need for artificial intelligence (AI) skills in the country has been growing, with online vacancies constituting 0.4% in 2022, leading to an increase in 2023 by 1.5%. Furthermore, initiatives such as Made in Germany Digital and the Federal Ministry for Digital and Transport’s (BMDV) AI action plans are also responsible for uplifting the overall market.

The foundry robots market in the UK is gaining increased exposure, owing to the existence of the defence and aerospace industries, which demand high-integrity castings that robots can rapidly produce with consistent quality. The country’s policy for supply chain dependency, as well as reshoring the government’s Made Smarter approach, are also uplifting the market’s development. According to an article published by the UK Business Government in June 2025, the country’s advanced Industrial Strategy is rapidly unlocking almost £4.3 billion in funding, which comprises nearly £2.8 billion for R&D for the upcoming five years, thus denoting a positive impact on the market.

North America Market Insights

North America in the foundry robots market is predicted to grow steadily by the end of the forecast duration. The market’s development in the region is fueled by progressive manufacturing strategies, along with a pressing requirement for securing supply chains and reshoring production. According to an article published by NLM in July 2022, 50% of employees require reskilling, owing to the Industry 4.0 technology adoption. In addition, 1/3rd of crucial skills will comprise technology competencies as of 2025, thereby making it suitable for the market’s development in the overall region.

The foundry robots market in the U.S. is growing significantly, owing to supportive government policies and funding initiatives. In addition, the strong presence of the automotive, aerospace, and defense sectors is opening lucrative doors for foundry robot manufacturers. As per a data report published by the U.S. Department of State in September 2024, the organization made the provision of USD 10 million to overcome the artificial intelligence accessibility barrier and instead promote computer credits access. Meanwhile, the foundry automation is being fast-tracked through initiatives such as the Manufacturing USA network and NIST’s Smart Manufacturing Innovation Centers.

The foundry robots market in Canada is also growing due to the tactical adoption of automation to boost the international competitiveness of heavy machinery and resource-based industries. The ultimate focus is effectively leveraging robotics to offer value to raw metal production, while uplifting the value chain into precision component manufacturing, especially for export purposes. Besides, as stated in the August 2024 Government of Canada article, the Minister of Public Services and Procurement declared a new project under the NGen’s approach to support 15 advanced manufacturing projects. This resulted in a generous fund provision of USD 59 million to readily support 31 organizations across the country, thereby creating an optimistic outlook for the market.