Foundry Binders Market Outlook:

Foundry Binders Market size was over USD 4.68 billion in 2025 and is projected to reach USD 7.7 billion by 2035, growing at around 5.1% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of foundry binders is evaluated at USD 4.89 billion.

Growing demand for precision machined metal parts from a variety of industries, including electronics, automotive, aircraft, and construction, has significantly impacted the expansion of the market. For instance, by 2023, the value of the world's construction industry is projected to reach USD 10.5 trillion. Therefore, the expansion of these industries is also bolstering the market growth. These components are essential for a variety of devices and machinery used in the society of today. For example, there is a great need in the car industry for strong, lightweight materials that can withstand harsh pollution restrictions and increase fuel efficiency. As a result, precision casting is given more importance, which increases the demand for contemporary foundry binders that provide accurate details and strong mold stability.

Because they have less of an adverse effect on the environment than traditional binders like clay or resin-bonded sand, foundry binders are frequently chosen. Typically, they come from renewable sources like sugars, starches, or artificial polymers. This aligns with the increased focus on sustainability and lowering industrial operations' carbon impact. Therefore, this is a major factor escalating the growth of the foundry binders market.

Key Foundry Binders Market Insights Summary:

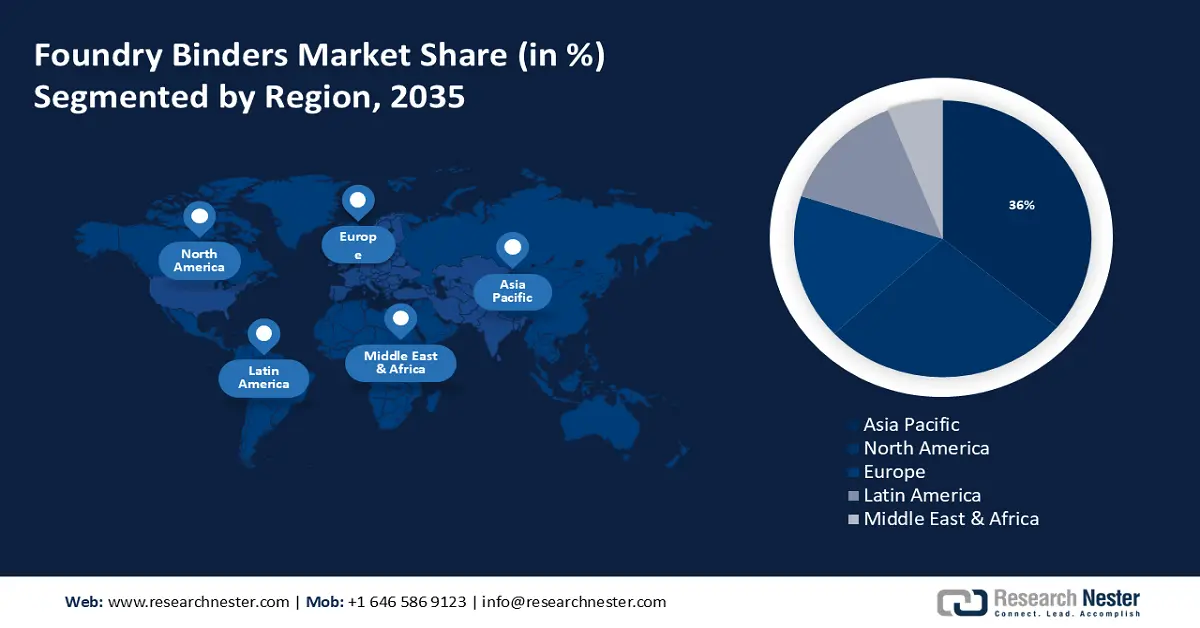

Regional Highlights:

- Asia Pacific foundry binders market is expected to capture 36% share by 2035, attributed to rapid industrialization and infrastructure investment in foundry-reliant industries.

- North America market will account for 27% share by 2035, driven by demand for sustainable production and high-performance binders.

Segment Insights:

- The core sand casting segment in the foundry binders market is expected to achieve a 53% share by 2035, fueled by technological advancements such as 3D-printed cores for casting.

- The organic segment in the foundry binders market is expected to achieve notable growth through 2035, driven by demand for sustainable materials and environmental concerns.

Key Growth Trends:

- Growing Demand for Metal Casting and 3D Printing

- Increased Shift Towards Miniaturized Electronic Products

Major Challenges:

- Higher Upfront Costs

- Increased Competition from Alternative Products may Hamper the Foundry Binders Market Growth

Key Players: ASK Chemicals, BASF SE, Mancuso Chemicals Limited, Imerys, Vesuvius, IVP Limited, John Winter, RP Minerals, The Shengquan Group (SQ), Eurotek Foundry Products Limited.

Global Foundry Binders Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 4.68 billion

- 2026 Market Size: USD 4.89 billion

- Projected Market Size: USD 7.7 billion by 2035

- Growth Forecasts: 5.1% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (36% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: China, United States, Germany, Japan, India

- Emerging Countries: China, India, Japan, South Korea, Thailand

Last updated on : 16 September, 2025

Foundry Binders Market Growth Drivers and Challenges:

Growth Drivers

- Growing Demand for Metal Casting and 3D Printing - Because 3D printing is becoming more and more popular in metal casting, there is a lot of opportunity in the foundry binders market. As 3D printing technology becomes more frequently employed in the manufacturing sector, there is an increasing need for binders that can successfully support the complex structures generated by additive manufacturing. Furthermore, this opens up new avenues for innovation and market growth by enabling the development of specialist binders that are specially made to satisfy the needs of 3D printing and metal casting. As per a report, 22% of 3D printer users report lead time reduction improvements of 25%–50%.

- Increased Shift Towards Miniaturized Electronic Products - The electronics industry's growing emphasis on performance improvement and size reduction has significantly increased demand for casting components. Precision casting is necessary to meet precise dimensions and tolerances for small components including housing sections, heat sinks, and connections. Significant advancements in binders and casting procedures have been made possible by the foundry industry's technological innovation, which has been spurred by increased demand for particular components.

- Surge in Demand for Lightweight Material and Sustainable Binder Formulations - Since the introduction of electric vehicles (EVs), reducing weight has become more and more significant. Because lighter EVs can travel farther on a single charge, consumers will find them more appealing, hastening the shift to environmentally friendly transportation. For instance, about 110 TWh of power was consumed by the global EV fleet in 2022, which is less than 0.5% of the world's current total final electricity consumption. In 2022, EVs replaced about 0.7 Mb/d (1.3 EJ) of oil. Manufacturers of foundry binders are creating binders that are specially designed to meet the demands of casting lightweight materials. The casting industry's growing emphasis on sustainability and economics drives the need for foundry binders. Furthermore, they will probably continue to play a significant role in the development of lightweight components that will influence transportation in the future.

Challenges

- Higher Upfront Costs - One of the main obstacles to the foundry binders market is the high upfront expenditures associated with deploying state-of-the-art binder technology. It may be necessary for foundries to incur significant capital costs to modernize their equipment and use innovative binder formulas. If the initial financial barrier discourages foundries, especially smaller ones, innovative binders may not be widely used. Therefore, financial considerations may also impede or delay the transition to more affordable and environmentally friendly binding alternatives.

- Increased Competition from Alternative Products may Hamper the Foundry Binders Market Growth

- Supply Chain Disruptions May Hinder Market Growth

Foundry Binders Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

5.1% |

|

Base Year Market Size (2025) |

USD 4.68 billion |

|

Forecast Year Market Size (2035) |

USD 7.7 billion |

|

Regional Scope |

|

Foundry Binders Market Segmentation:

Product Type Segment Analysis

Organic segment in the foundry binders market is expected to hold a share of 33% during the forecast period. In the upcoming years, there is anticipated to be a significant expansion in the market for organic binders. Demand for organic binders has surged across various end-use industries due to increased environmental concerns and the need for sustainable materials. Because of their better compressive strength and reduced carbon emissions, organic binders have been widely adopted, especially in the construction sector. Furthermore, producers are concentrating on creating organic, non-toxic substitutes due to growing awareness of the detrimental effects of synthetic binders on the environment and human health. Growth in the industry is anticipated as a result of this switch to organic binders.

End-users Segment Analysis

Core sand casting segment in the foundry binders market is expected to hold a share of 53% during the forecast period. To create holes, undercuts, and cavities during the casting process that cannot be created directly during the casting process, a core is employed. The final cavity core type, design, and molten metal composition all play a role in selecting the core type.

Also, technological advancements such as 3D-printed cores for casting are driving the growth of the segment. The 3D printer can print the cores, which can then be inserted into a traditional mold. The technology avoids the time-consuming, conventional fabrication and assembly of the complex cores and minimizes subsequent machining, which results in fewer pieces and a significantly less tedious mold creation process. Up to a specific batch size, 3D printing is always more cost-effective than conventional methods overall since there are no tool costs. Therefore, the factors are propelling the growth of the segment.

Our in-depth analysis of the global foundry binders market includes the following segments:

|

Product Type |

|

|

Application |

|

|

Application |

|

|

End-users |

|

|

Industry Structure |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Foundry Binders Market Regional Analysis:

APAC Market Insights

Asia Pacific industry is estimated to account for largest revenue share of 36% by 2035. This region dominated the market because of its substantial presence in several foundry-dependent industries, including the manufacturing of machinery, automobiles, and aircraft. For instance, in 2021, there were 1.8 thousand narrow-body aircraft in the Asia Pacific aircraft fleet. The growth of the foundry binders market in the region was significantly influenced by South Korea, Japan, China, India, and other causes. In addition, the rapid industrialization, population growth, and increased investments in infrastructure development in the Asia Pacific region created a substantial demand for metal castings, which in turn fueled a need for foundry binders. Technological developments, favorable government regulations, and the region's capacity for cost-effective production all contributed to its supremacy in the foundry-binding industry.

North American Market Insights

North American Foundry Binders Market is projected to hold a share of 27% by the end of 2035. The region's manufacturing industry is booming, particularly in industries like aerospace, defense, and automotive that rely significantly on metal castings. The market has expanded in North America due to factors such as the increased emphasis on ecologically friendly and sustainable production processes, the requirement for high-performance foundry binders, and technical improvements. Furthermore, the region's strong focus on research and development, along with the presence of important industry players and beneficial government regulations, have all contributed to the expansion of the North American foundry binders market.

Foundry Binders Market Players:

- ASK Chemicals

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- BASF SE

- Mancuso Chemicals Limited

- Imerys

- Vesuvius

- IVP Limited

- John Winter

- RP Minerals

- The Shengquan Group (SQ)

- Eurotek Foundry Products Limited

Recent Developments

- January 2024 - A leading company in the world of foundry chemicals, ASK Chemicals, is pleased to announce that it will be attending the forthcoming International Foundry Exhibition (IFEX) in Bangalore. This fully functional, first-rate manufacturing facility is prepared to provide cutting-edge foundry services and other industrial solutions to meet the expanding needs of the Asian and Indian markets. With novel binders for steel and iron casting applications and the industry-leading SOLITEC coating technology for unmatched quality and dependability in high-production automotive situations, ASK Chemicals India is happy to introduce several innovative solutions. Additionally, the company's REZIANCE resin solutions for refractory applications will be showcased.

- January 2022 - For many years, voestalpine has been at the forefront of metal 3D printing. Its own 3D printing facilities and research facilities throughout the globe are already using these metals. At its location in Traisen, Lower Austria, the Steel and Technology Group has now begun using the most sophisticated 3D sand printer in Europe for heavy steel castings. Compared to the old method, the new additive manufacturing technology for silica sand-based advanced casting production shortens production times and is more ecologically friendly.

- Report ID: 5956

- Published Date: Sep 16, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Foundry Binders Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.