Dust Suppression Control Market Outlook:

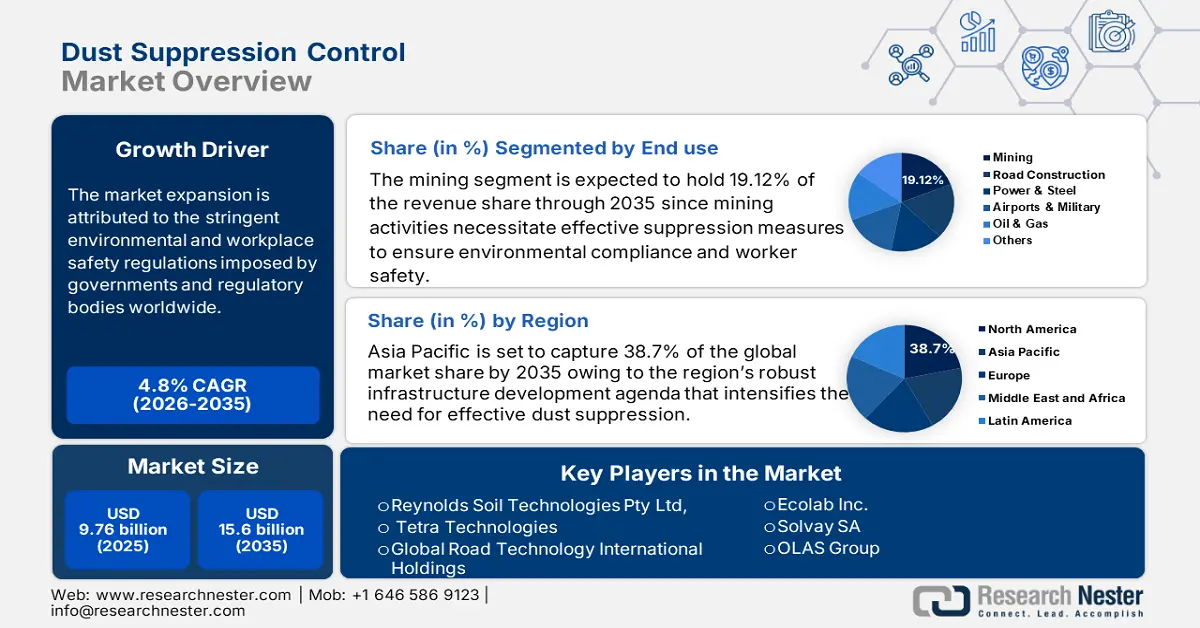

Dust Suppression Control Market size was valued at USD 9.76 billion in 2025 and is likely to cross USD 15.6 billion by 2035, registering more than 4.8% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of dust suppression control is assessed at USD 10.18 billion.

The dust suppression control market expansion is attributed to the stringent environmental and workplace safety regulations imposed by governments and regulatory bodies worldwide. These regulations require industries to control dust emissions to protect human health, maintain air quality, and reduce environmental impact. Governments and regulatory bodies such as the Occupational Safety and Health Administration (OSHA), the United States Environmental Protection Agency (EPA), and The European Agency for Safety and Health at Work (EU-OSHA) impose strict dust control requirements to protect worker health and the environment. Industries such as mining, construction, manufacturing, and agriculture must adopt dust suppression solutions to comply with these regulations, boosting dust suppression control market demand.

The U.S. EPA has established the National Ambient Air Quality Standards (NAAQS) to regulate particulate matter, including dust from construction activities. The EPA’s 2020 National Emissions Inventory Technical Support Document highlights that dust emissions from road construction are generally controlled by watering the construction site, achieving a control efficiency of approximately 50% for particulate matter (PM10 and PM25) emissions. Regular water application to construction sites can reduce dust emissions by up to 68%.

Additionally, government investments in infrastructure projects, such as road construction and mining, necessitate effective dust control to minimize environmental impact and comply with regulations. For instance, in June 2022, India’s Minister of Road Transport and Highways inaugurated 15 national highway projects worth USD 1.7 billion in Bihar, highlighting the emphasis on infrastructure development.

Dust suppression systems have varying production capacities depending on their specific types and manufacturers. For instance, Oasis Irrigation Equipment Company Limited has a production capacity of 20 units for its industrial dust suppression systems. On the other hand, Janvik Engineers and Tubes Private Limited has a production capacity of 50 per month for dust control systems for concrete industries.

Key Dust Suppression Control Market Insights Summary:

Regional Highlights:

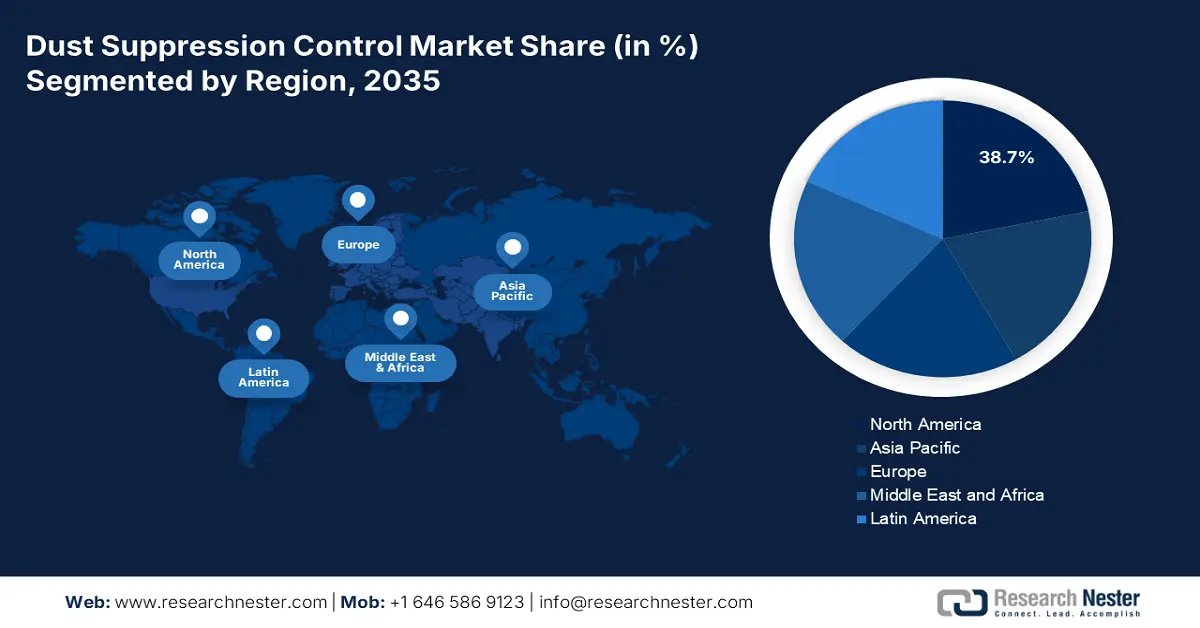

- Asia Pacific holds a 38.70% share in the Dust Suppression Control Market, driven by infrastructure investments and dust control needs in China and India, positioning it for significant growth by 2035.

- North America's dust suppression control market is projected for lucrative share growth by 2035, driven by infrastructure development and need for sustainable dust suppression.

Segment Insights:

- The Mining segment is expected to hold a 19.12% market share by 2035, fueled by increased mining activities and stringent environmental and health regulations.

Key Growth Trends:

- Technological advancements

- Rising concerns for worker health and safety

Major Challenges:

- Water scarcity issues impacting dust suppression method

- Technical limitations and integration challenges

- Key Players: Reynolds Soil Technologies Pty Ltd, Tetra Technologies, Global Road Technology International Holdings, Ecolab Inc., Solvay SA, Borregaard ASA, OLAS Group.

Global Dust Suppression Control Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 9.76 billion

- 2026 Market Size: USD 10.18 billion

- Projected Market Size: USD 15.6 billion by 2035

- Growth Forecasts: 4.8% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (38.7% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: China, United States, Japan, Germany, South Korea

- Emerging Countries: China, India, Brazil, Mexico, Thailand

Last updated on : 13 August, 2025

Dust Suppression Control Market Growth Drivers and Challenges:

Growth Drivers

- Technological advancements: The dust suppression control market is experiencing a transformation with the adoption of smart technologies that enhance efficiency, automation, and real-time monitoring. These advancements drive dust suppression control market growth by improving compliance, reducing operational costs, and increasing environmental sustainability. Internet of Things (IoT) sensors are integrated into dust suppression systems to provide real-time monitoring of airborne dust levels. These systems automatically adjust suppression mechanisms based on air quality data, optimizing water and chemical usage. Key players like Trolex and Sensidyne offer smart dust monitoring solutions for industrial applications.

AI-driven automation allows dust control systems to predict dust accumulation and adjust misting or suppressant application accordingly. Smart misting systems use AI algorithms to control spray intensity based on weather conditions and dust concentration. Moreover, drones equipped with AI can autonomously detect dust hotspots and apply suppressants efficiently in mining, construction, and quarrying sites.

AI-powered dust management systems start by gathering data in real-time from a network of smart sensors and monitoring equipment that are positioned thoughtfully throughout the property. These sensors evaluate a range of information, such as air quality indices, weather, particulate matter concentrations, and other significant environmental factors. - Rising concerns for worker health and safety: Health risks associated with dust exposure such as prolonged exposure to respirable crystalline silica (RCS) lead to silicosis, lung cancer, and chronic obstructive pulmonary disease (COPD). According to the Occupational Safety and Health Administration, U.S. Department of Labor, approximately 2.3 million people in the U.S. are exposed to silica during work. Miners and industrial workers face risks from coal dust (black lung disease) and metal dust (pulmonary fibrosis). Further workers in construction, agriculture, and manufacturing experience allergies and eye irritations due to airborne dust particles.

Regulatory bodies such as OSHA, EPA & EU, and ISO & WHO are promoting worker safety by encouraging the use of dust suppression technologies. Fines for non-compliance can reach millions of dollars, promoting businesses to invest in advanced suppression technology. Worker health concerns are not only shaping safety regulations but also driving innovation in dust suppression technologies. As businesses prioritize employee well-being, the demand for automated, AI-powered, and sustainable dust control solutions will continue to rise.

Challenges

- Water scarcity issues impacting dust suppression methods: A single large mining site can use millions of gallons of water per month for dust control. Frequent water spraying is needed to suppress dust from roads, demolition, and earthmoving. Soil erosion prevention and factory air quality control rely on water misting. In water-scarce regions, industries are forced to cut water usage, limiting the effectiveness of traditional dust control methods.

Furthermore, governments are implementing strict water conservation policies due to climate change and declining freshwater sources.Regulatory bodies are restricting excessive water usage in industrial applications. Thus, businesses must invest in water-efficient or chemical-based alternatives, increasing operational costs. - Technical limitations and integration challenges: Certain technologies may underperform in extreme weather conditions, reducing their applicability. Dependence on real-time data from sensors can be problematic in areas with unstable network connectivity. Moreover, aligning new dust suppression systems with existing industrial equipment and processes can be complex and costly. Retrofitting facilities may lead to temporary halts in production, affecting overall efficiency.

Dust Suppression Control Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

4.8% |

|

Base Year Market Size (2025) |

USD 9.76 billion |

|

Forecast Year Market Size (2035) |

USD 15.6 billion |

|

Regional Scope |

|

Dust Suppression Control Market Segmentation:

End use (Mining, Road Construction, Airports & Military, Oil & Gas, Power & Steel)

Mining segment is anticipated to capture around 19.12% dust suppression control market share by the end of 2035. Mining activities, including drilling, blasting, material handling, and transportation, generate substantial amounts of dust, necessitating effective suppression measures to ensure environmental compliance and worker safety. The global increase in mining activities to meet the rising demand for minerals and resources has led to higher dust emissions. This escalation necessitates the adoption of efficient dust suppression solutions to manage environmental and health concerns.

Stringent environmental and occupational health regulations mandate the implementation of effective dust control measures in mining sites to protect workers and surrounding communities, thereby driving the demand for dust suppression products. Further, growing awareness of the environmental impact of mining activities has led to increased adoption of dust suppression chemicals and systems to minimize air pollution and ecological degradation.

Chemical (Lignin Sulfonate, Calcium Chloride, Magnesium Chloride, Polymeric Emulsions)

The calcium chloride segment in dust suppression control market is witnessing substantial growth during the assessed period. Calcium chloride’s ability to attract and retain moisture helps keep road surfaces damp, thereby reducing dust emissions. Moreover, compared to other chemical suppressants, calcium chloride is affordable and efficient, making it a preferred choice for dust control. Its effectiveness over various gravel types and weather conditions enhances road surface stability and reduces maintenance costs. By lowering the freezing point of moisture in road surfaces, calcium chloride prevents winter road damage, contributing to environmental preservation.

Calcium chloride is a versatile and effective agent in the dust suppression control market, available in various forms to suit different applications. Occidental Petroleum Corporation provides two forms of calcium chloride: LIQUIDOW Technical Grade Calcium Chloride Solution is available in concentrations ranging from 28-42%. The suggested solid products for dust control are Anhydrous Calcium Chloride 94-97% Mini Pellets and DowFlake Xtra 83-87% Calcium Chloride Flakes.

In terms of exports, countries with significant production capabilities of calcium chloride, such as China, and the U.S., are likely to see an increase in export activities as demand for dust control solutions rises globally, especially in regions experiencing rapid industrialization and urbanization.

Calcium chloride exports by country in 2023:

|

Exporters |

Trade Value 1000USD |

Quantity |

Unit |

|

China |

281,278.89 |

1,356,200,000 |

kg |

|

European Union |

54,075.86 |

56,716,400 |

kg |

|

U.S. |

54,057.88 |

149,143,000 |

kg |

|

Netherlands |

49,371.04 |

192,250,000 |

kg |

|

Egypt, Arab Republic |

35,233.11 |

- |

- |

Source: WITS

Our in-depth analysis of the global dust suppression control market includes the following segments:

|

Chemical |

|

|

End use |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Dust Suppression Control Market Regional Analysis:

APAC Market Analysis

Asia Pacific dust suppression control market is expected to hold the largest revenue share of 38.7% by 2035. Significant investments in infrastructure projects, particularly in countries like China and India are boosting the demand for dust suppression chemicals in road construction and other development activities.

China’s dust suppression control market is poised for continued growth, supported by technological advancements and a heightened focus on sustainable practices. The development of innovative, environmentally friendly dust control solutions is expected to create new opportunities in the market. the country’s dynamic landscape and regulatory environment are key factors propelling the expansion of the dust suppression control market. Additionally, in India growing awareness of the health risks associated with dust exposure has led to increased implementation of dust control measures across various sectors to protect workers and nearby communities.

North America Market Statistics

North America dust suppression control market is expected to register lucrative growth during the period 2026-2035. The region’s robust infrastructure development agenda intensifies the need for effective dust suppression. As construction and mining activities expand, the demand for specialized, sustainable dust control equipment tailored to specific applications is increasing.

The U.S. enforces rigorous environmental standards aimed at reducing airborne particulate matter. Industries are compelled to adopt effective dust suppression methods to comply with these regulations, thereby promoting the use of sustainable solutions. Additionally, key players are at the forefront of developing innovative solutions to meet the growing demand for effective dust suppression in the country. Donaldson Company, Inc. specializes in filtration systems for dust control across various industries.

In Canada, ongoing infrastructure projects, including road construction and urban development, necessitate effective dust control measures to ensure environmental compliance and public health. The country’s environmental policies mandate industries to implement dust control solutions, thus, driving market demand.

Key Dust Suppression Control Market Players:

- Benetech, Inc.

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Reynolds Soil Technologies Pty Ltd

- Tetra Technologies

- Global Road Technology International Holdings

- Ecolab Inc.

- Solvay SA

- Borregaard ASA

- OLAS Group

- Oasis Irrigation Equipment Company Limited

- Janvik Engineers and Tubes Private Limited

- Cargill Inc.

Leading players are actively involved in educating industries about the benefits of dust suppression and the importance of using compliant products. This advocacy can drive adoption, especially in markets where dust control is less regulated. By combining innovation, sustainability, strategic partnerships, and expanding market access, key players in the dust suppression control market continue to drive its growth while addressing the increasing demand for efficient, safe, and eco-friendly solutions.

Recent Developments

- In April 2024, Global Road Technology (GRT) and TotalEnergies Marketing Australia presented their world-leading particulate pollution control solution at the 2024 Queensland Mining Industry Health and Safety Conference. GRT's Australian-made SMART Dosing Unit, which has received a Queensland government innovation grant, is an automated dosing device designed to improve the performance of dust suppression and water management systems on mine sites and was the centerpiece of its presentation.

- In August 2022, TETRA Technologies, Inc. announced that it has signed exclusive technology licensing agreements with KMX Technologies LLC and Hyrec Holdings Company W.L.L. for the recycling of produced water for beneficial reuse in a variety of applications, including agricultural and crop irrigation, industrial, power generation, construction, groundwater recharge, cooling towers, and dust control. TETRA is a market leader in treating and recycling generated water from oil and gas wells for hydraulic fracturing.

- Report ID: 7175

- Published Date: Aug 13, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Dust Suppression Control Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.