Coordinate Measuring Machine Market Outlook:

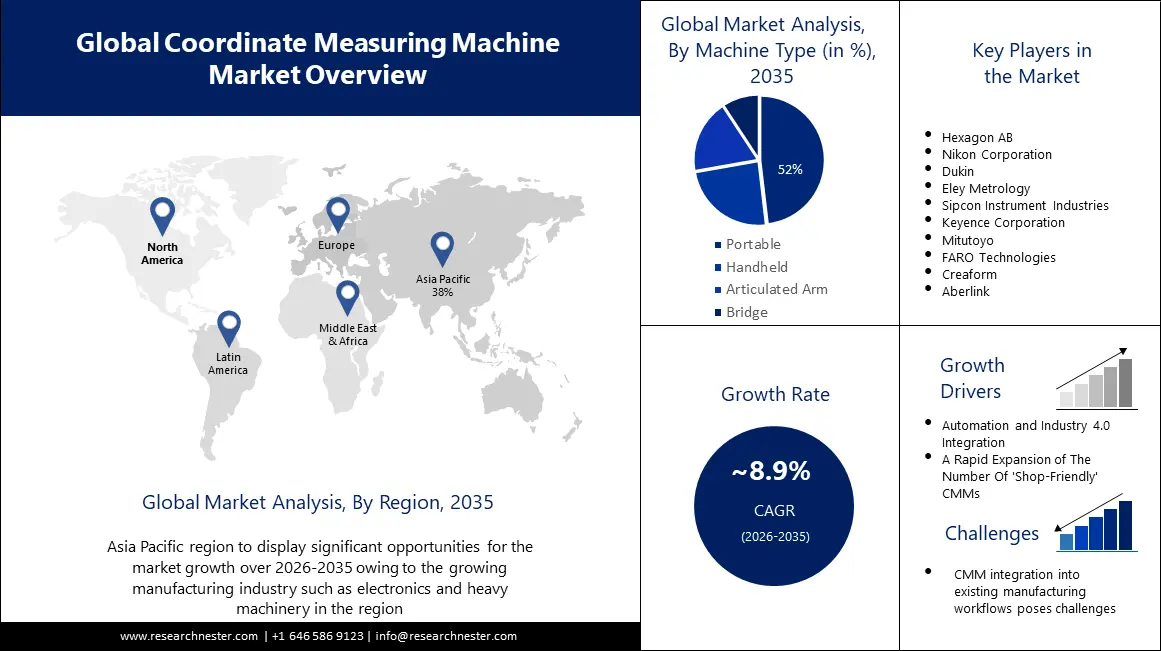

Coordinate Measuring Machine Market size was valued at USD 3.92 billion in 2025 and is set to exceed USD 9.2 billion by 2035, expanding at over 8.9% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of coordinate measuring machine is estimated at USD 4.23 billion.

The rise in the need for high quality products in a competitive market has led to a surge, in precision manufacturing. To meet this rising demand companies are investing in machinery and technologies like coordinate measuring machines (CMMs).

With the increasing emphasis on meeting regulatory standards and customer demands there is a growing need for advanced metrology solutions such, as CMMs. This is driven by the importance placed on quality control and inspection. CMMs offer manufacturers the ability to achieve dependable measurements allowing them to verify the dimensional precision of components detect any imperfections and guarantee adherence, to quality standards.

Key Coordinate Measuring Machine Market Insights Summary:

Regional Highlights:

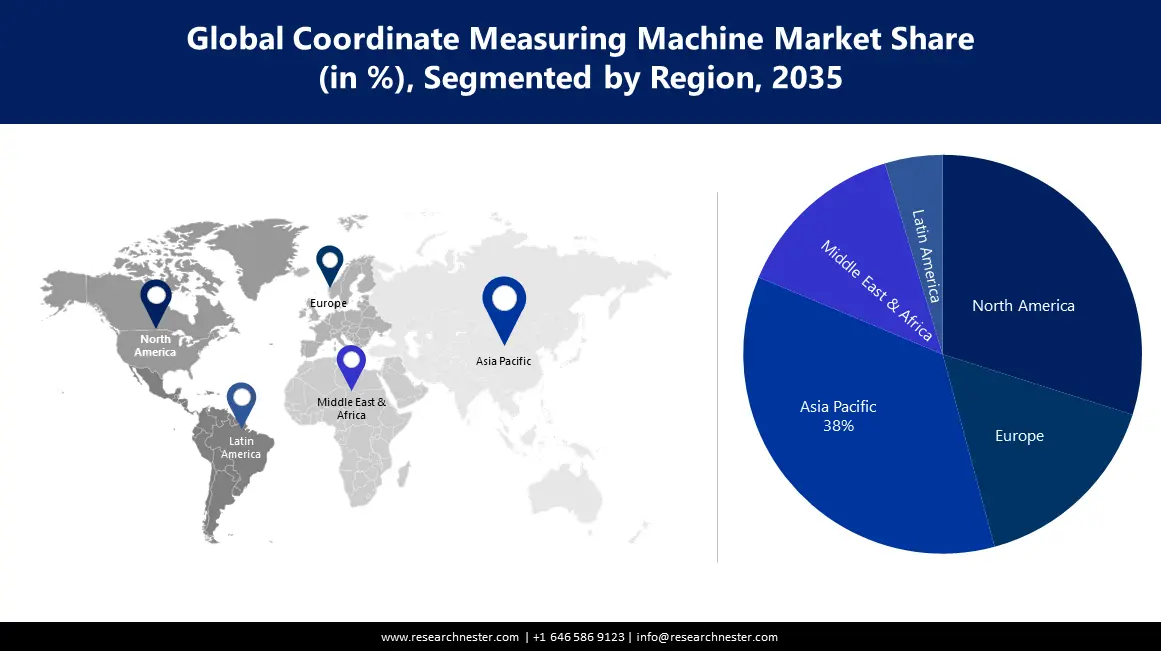

- The Asia Pacific coordinate measuring machine (cmm) market will dominate more than 38% share by 2035, driven by growing manufacturing industries such as electronics and heavy machinery.

- The North America market will account for 32% share by 2035, attributed to growing demand for automation and industrial integration in automotive and aerospace sectors.

Segment Insights:

- The portable segment in the coordinate measuring machine market is projected to secure a 52% share by 2035, driven by rising demand from the automotive industry for accurate and portable measurement solutions.

- The heavy machinery segment in the coordinate measuring machine market is anticipated to achieve a 47% share by 2035, attributed to rising demand for efficient heavy machinery in construction and mining sectors.

Key Growth Trends:

- Automation and Industry 4.0 Integration

- Advancements in CMM Technology

Major Challenges:

- CMMs are expensive, especially for small and medium-sized businesses (SMEs).

Key Players: Hexagon AB, Nikon Corporation, Dukin, Eley Metrology, Sipcon Instrument Industries, Keyence Corporation, Mitutoyo, FARO Technologies, Creaform, Aberlink.

Global Coordinate Measuring Machine Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 3.92 billion

- 2026 Market Size: USD 4.23 billion

- Projected Market Size: USD 9.2 billion by 2035

- Growth Forecasts: 8.9% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (38% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: United States, Germany, China, Japan, Italy

- Emerging Countries: China, India, Japan, South Korea, Thailand

Last updated on : 11 September, 2025

Coordinate Measuring Machine Market Growth Drivers and Challenges:

Growth Drivers

-

Automation and Industry 4.0 Integration: The digital transformation of CMMs with automation and Industry 4.0 technologies is driving market growth. In 2021 the number of acquisitions related to Industry 4.0 reached its point surpassing 130. This represents an increase of 115%, over the past decade. Advanced CMM systems now feature automation capabilities, including robotic loading and unloading, automated data collection, and real-time monitoring. This integration enhances productivity, reduces manual intervention, and enables seamless integration into smart manufacturing environments.

- A Rapid Expansion of The Number Of 'Shop-Friendly' CMMs - There has been an increase in the number of CMMs designed to be user-friendly and placed directly on the production floor to keep up with production rates. For instance, the Zeiss Duramax maximizes the use of its footprint as a large portion of the floor space is dedicated to measuring volume. Its open-frame design makes it suitable for automation. Further, a robotic part loading system for CMMs has also been launched by Hexagon's Manufacturing Intelligence division designed to allow manufacturers to maintain inspection throughput without requiring operator intervention.

- Advancements in CMM Technology: Technological advancements in CMMs, such as improved accuracy, faster scanning speeds, enhanced software capabilities, and the integration of non-contact measurement techniques (such as optical and laser scanning), are driving market growth. These advancements enable more efficient and comprehensive measurement capabilities, reducing inspection time and increasing overall productivity.

Challenges

-

Increasing Complexity of Technology: A CMM is a complex machine that requires skilled operators with metrology and measurement expertise. As technology advances and evolves, it can be difficult to train and retain qualified personnel to operate and maintain CMMs. Additionally, since CMMs are highly complex machines, they require regular maintenance and calibration in order to ensure the accuracy of the measurements.

- CMM integration into existing manufacturing workflows poses challenges.

- CMMs are expensive, especially for small and medium-sized businesses (SMEs).

Coordinate Measuring Machine Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

8.9% |

|

Base Year Market Size (2025) |

USD 3.92 billion |

|

Forecast Year Market Size (2035) |

USD 9.2 billion |

|

Regional Scope |

|

Coordinate Measuring Machine Market Segmentation:

Machine Type Segment Analysis

The portable segment in the coordinate measuring machine market is estimated to gain the largest revenue share of about 52% in the year 2035 attributed to the rising demand from the automotive industry for highly accurate measurement solutions. The portability of these machines allows users to take them to different locations and environments making them suitable for a variety of applications such as automotive parts inspection and machine tool calibration. Additionally, the development of new technologies such as laser trackers and optical trackers has made portable CMM systems even more accurate and efficient.

Industry Segment Analysis

Coordinate measuring machine market from the heavy machinery segment is estimated to gain a significant share of about 47% in the year 2035. This is because CMMs allow for more accurate measurements of heavy machinery parts and components. This leads to higher quality and better performance of machinery, which is essential in industries such as earthmoving, excavation, and agricultural machinery.

Moreover, the rising demand for efficient and cost-effective heavy machinery in the construction and mining industry along with the increased focus on automation and the development of new technologies to improve heavy machinery efficiency is expected to further boost the segment's growth.

Our in-depth analysis of the global market includes the following segments:

|

Machine Type |

|

|

Application |

|

|

Industry |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Coordinate Measuring Machine Market Regional Analysis:

APAC Market Insights

Coordinate measuring machine market in Asia Pacific, amongst the market in all the other regions, is anticipated to hold the largest with a share of about 38% by the end of 2035. The growing manufacturing industry such as electronics and heavy machinery in the region, will lead to increased demand for CMMs, as manufacturers seek to improve the accuracy and precision of their products. Observations indicate that China's manufacturing output in 2021 increased by 27% from that of 2020, reaching USD 4,866 billion.

Moreover, with more auto parts manufacturers in the region, especially in India, China, and Japan, automotive companies are investing heavily in automation technologies to reduce production costs and increase productivity.

North American Market Insights

The North American coordinate measuring machine market is estimated to be the second largest, registering a share of about 32% by the end of 2035 attributed majorly to the growing demand for automation and integration of industrial production processes in the automotive and aerospace industries. As more companies in the region are looking to increase their production capacities and reduce labor costs, the demand for coordinate measuring machines is expected to increase.

In addition, technological advancements in the field of machine vision and 3D imaging have increased accuracy and speed, allowing for more accurate quality control and faster feedback, both of which are essential for modern production.

Coordinate Measuring Machine Market Players:

- Hexagon AB

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Nikon Corporation

- Dukin

- Eley Metrology

- Sipcon Instrument Industries

- Keyence Corporation

- Mitutoyo

- FARO Technologies

- Creaform

- Aberlink

Recent Developments

- Nikon Corporation (Nikon) recently introduced the models in their NEXIV CNC Video Measuring System, namely the VMZ S4540 and VMZ S6555. These innovative systems are designed for efficient automated dimensional measurement, in inline processes.

- A new series of Leitz PMM-C coordinate measuring machines (CMMs) has been introduced by Hexagon AB's Manufacturing Intelligence business. The Leitz PMM-C model employs ultra-high precision fixed probe heads to achieve the most precise measurements in high-precision applications with very tight form tolerances.

- Report ID: 5118

- Published Date: Sep 11, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Coordinate Measuring Machine Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.