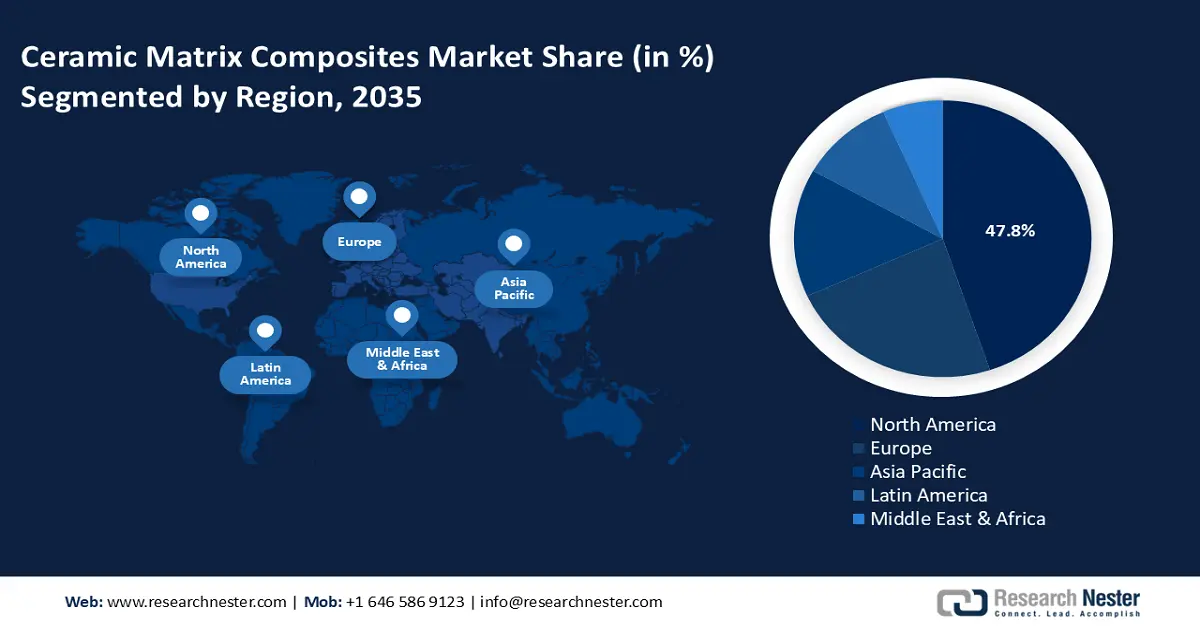

Ceramic Matrix Composites Market Regional Analysis:

North America Market Insights

North America led the ceramic matrix composites market with a revenue share of 47.8%, driven by technological advancements and robust demand from the aerospace sector. In the U.S., the thriving aerospace industry continues to fuel CMC adoption, particularly in turbine engines, thermal shields, and airframes. These composite materials provide exceptional mechanical strength, resistance to high temperatures, and lightweight characteristics, which are essential for improving fuel efficiency and performance in aircraft used for commercial, military, and space exploration purposes. The growing emphasis on next-generation aerospace technologies, including hypersonic and reusable space vehicles, further strengthens the U.S. market outlook.

Canada is also contributing to the regional ceramic matrix composites market through increasing investments in advanced materials research and sustainable aviation initiatives. The country’s commitment to decarbonizing aerospace and defense operations encourages the exploration of innovative high-performance materials like CMCs. Raytheon Technologies, through its Pratt & Whitney division, serves as a prominent instance in this region. The company integrates CMCs into advanced jet engine components to enhance thermal efficiency and durability, supporting performance goals while aligning with environmental mandates.

Europe Market Insights

Europe's strategic transition towards sustainable energy and advanced manufacturing is driving the expansion of the ceramic matrix composites market, especially in the UK and Germany. In the UK, the emphasis on next-generation energy solutions, including nuclear fusion and high-efficiency thermal systems, has increased the demand for CMCs because of their exceptional resistance to high temperatures and radiation. These composites are increasingly used in components for nuclear reactors and clean energy infrastructure, supporting the UK’s long-term energy resilience and decarbonization targets.

On the other hand, Germany is witnessing rapid CMC adoption in the automotive sector. As a global automotive hub, Germany is prioritizing lightweight, high-performance materials to enhance vehicle efficiency and meet stringent emission regulations. Ceramic matrix composites are being integrated into high-temperature vehicle components such as brake discs, turbochargers, and exhaust systems. Their capacity to enhance fuel efficiency and endure harsh conditions renders them crucial for the advancement of electric and high-performance automobiles. Brembo collaborates with SGL Carbon Ceramic Brakes GmbH to supply advanced CMC brake systems to top automotive brands, including Porsche and Ferrari, reinforcing Germany’s leadership in high-performance mobility solutions.