Bioplastics Market Outlook:

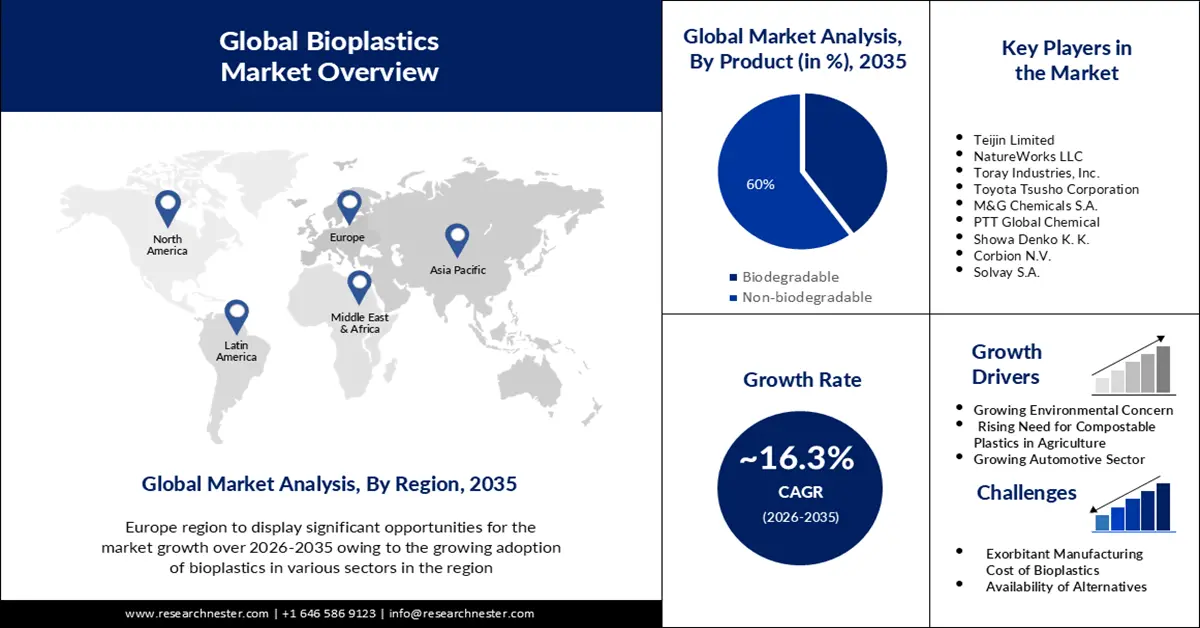

Bioplastics Market size was over USD 16.96 billion in 2025 and is anticipated to cross USD 76.78 billion by 2035, growing at more than 16.3% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of bioplastics is assessed at USD 19.45 billion.

The worldwide production capacity of bioplastics in 2024 was 2.47 million tons and is projected to cross 5.73 million tons by the end of 2029. The comparative analysis of 2024’s production capacities and true production suggests that the market has been operating at about 60% capacity. However, this rate varies significantly based on polymer type, ranging between 35% and 100%. The average utilization rate was 58% in 2024 (2.47 million tons in capacity vs. 1.44 million tons yield). The global bioplastics manufacturing industry resurfaced in 2023 after stagnation over the past few years, and massive growth is expected by 2028, when the yield is likely to reach 7.43 million tons from 2.18 million tons in 2023. Additionally, it is notable that more than 50% of bioplastics are biodegradable, with polylactic acid (PLA) being the most popular alternative.

Global Production Capacities of Bioplastics 2024-2029

Source: European Bioplastics

Bioplastics Production at Close to 60% Capacity in 2024

Source: European Bioplastics

Production volumes, leading suppliers, and main applications for some of the most important commercial bio-based polymers, 2020

|

Bio-based polymer |

Global capacity (tons) |

Major producer |

Application |

|

Starch and blends |

435K |

Futerro, Novamont, Biome |

Flexible packaging, consumer goods, and agriculture |

|

Polylactic acid (PLA) |

435K |

NatureWorks, Evonik, Total Corbion PLA |

Flexible packaging, Rigid packaging, consumer goods |

|

Polyhydroxyalkanoates (PHA) |

40K |

Yield10 Bioscience, Tianjin GreenBio Materials, Bio-on |

Flexible packaging, Rigid packaging |

|

Polyethylene (PE) |

244K |

Neste, LyondellBasell |

Flexible packaging, Rigid packaging |

|

Polyethylene terephthalate (PET) |

181K |

Toray Industries, The Coca-Cola Company, MSG Chemicals |

Rigid packaging |

|

Polybutylene adipate terephthalate (PBAT) |

314K |

Algix, BASF |

Flexible packaging, Rigid packaging, agriculture |

|

Polybutylene succinate (PBS) |

95K |

Roquefte, Mitsubishi Chem., Succinity |

Flexible packaging, agriculture |

Source: CAS

The bioplastic traction is primarily supported by government aid and grants to foster sustainability-focused businesses. In October 2024, the U.S. National Science Foundation (NSF) and partner agencies in Canada, the U.S., Finland, the Republic of Korea, Japan, and the UK announced funding awards worth USD 82 million toward advancing bioeconomy research. The NSF Global Centers 2024 program provisions multidisciplinary yet holistic projects that bring together public engagement and international scientific disciplines to boost manufacturing processes, including the operations of the Global Center for Sustainable Bioproducts (GCSB) at the University of Tennessee. It leverages international collaborations and their expertise to diversify the approaches for utilizing waste biomass.

NSF Global Centers 2024 program partner agencies comprise the Canada’s Natural Sciences and Engineering Research Council (NSERC) and the Social Sciences and Humanities Research Council (SSHRC), the U.S.-based National Endowment for the Humanities, Innovation Funding Agency Business Finland, the Research Council of Finland (RCF), the Japan Science and Technology Agency (JST), the Republic of Korea and the National Research Foundation, the Ministry of Science, and the U.K. Research and Innovation (UKRI) Biotechnology and Biological Sciences Research Council.

In September 2024, the U.S Department of Defense (DoD) announced an addition of 12 awards as part of its Distributed Bioindustrial Manufacturing Program (DBIMP) to bioindustrial firms, thereby bringing the award count to 25, worth USD 42 million. As part of the awarded projects so far, Nebraska-based Bluestem Biosciences received USD 2.16 million to build an anaerobic fermentation plant for developing an organic acid as a precursor for defense-related polymers/bioplastics and adhesive fabrication.