Aluminum Die Casting Mold Release Agents Market Outlook:

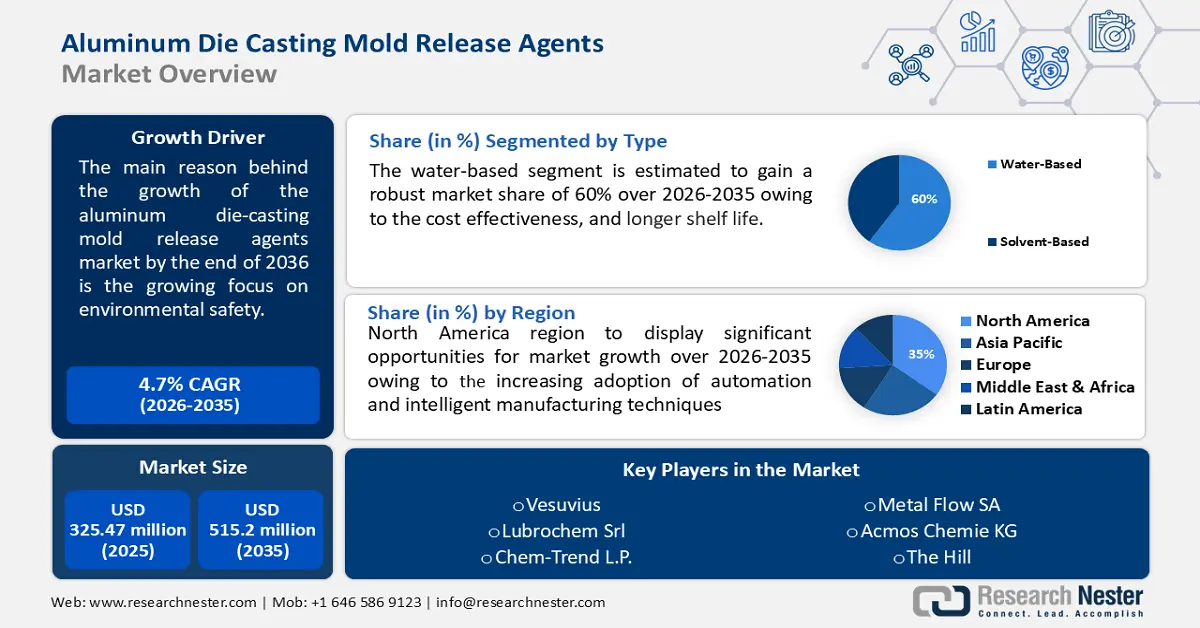

Aluminum Die Casting Mold Release Agents Market size was valued at USD 325.47 million in 2025 and is likely to cross USD 515.2 million by 2035, expanding at more than 4.7% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of aluminum die casting mold release agents is assessed at USD 339.24 million.

The increasing focus on harmless environmental solutions is a notable development in the market. As manufacturers become more aware of environmental issues, they are actively seeking alternatives having negligible impact on the environment. As a result, water and bio-based molding solvents have been developed and used. According to the report in Nov 2021, the chemical industry consumes more than 10% of fossil fuels across the world and releases around 3.3 gigatons of greenhouse gases annually.

Key Aluminum Die Casting Mold Release Agents Market Insights Summary:

Regional Highlights:

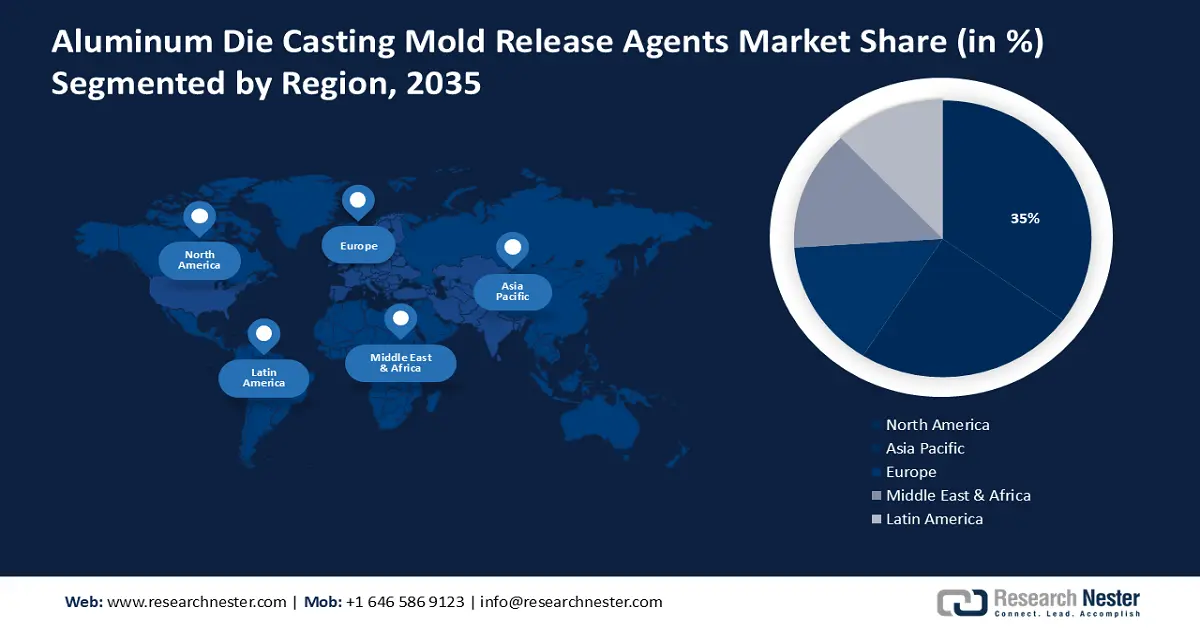

- North America is anticipated to command a 35% revenue share in the aluminum die casting mold release agents market by 2035, stemming from the region’s rising implementation of automation and intelligent manufacturing techniques.

- The Asia Pacific region is projected to secure the second-highest share by 2035 as expansion accelerates, fueled by population growth, urbanization, and increasing demand for smart cities alongside evolving industrial regulations.

Segment Insights:

- The water-based segment in the aluminum die casting mold release agents market is expected to register a CAGR of over 60% through 2035, propelled by its non-toxic formulation, reduced VOC emissions, straightforward application, and longer shelf life.

- The application segment is predicted to exceed a 40% share by 2035, supported by its critical role in ensuring heat stability, minimizing residual waste, and enabling efficient casting of aluminum components.

Key Growth Trends:

- Growing demand for aluminum die cast products in the automobile sector

- Integration of advanced dispensing technology for enhancing efficiency and reducing waste

Major Challenges:

- Strict regulations for environmental protection

- Disruption in the supply chain due to improper management

Key Players: Henkel AG and Company, Merck KGaA, FUCHS LUBRITECH GmbH, Vesuvius, Chem-Trend L.P., METAL FLOW SA, ACMOS CHEMIE KG, Quaker Chemical Corporation, Lubrochem Srl, The HILL.

Global Aluminum Die Casting Mold Release Agents Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 325.47 million

- 2026 Market Size: USD 339.24 million

- Projected Market Size: USD 515.2 million by 2035

- Growth Forecasts: 4.7%

Key Regional Dynamics:

- Largest Region: North America (35% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: United States, China, Germany, Japan, South Korea

- Emerging Countries: India, Vietnam, Indonesia, Mexico, Thailand

Last updated on : 1 December, 2025

Aluminum Die Casting Mold Release Agents Market - Growth Drivers and Challenges

Growth Drivers

- Growing demand for aluminum die cast products in the automobile sector - The automotive market is one of the biggest end-user markets for aluminum die cast products and their components. Aluminum die casting mold release agents are used in several important automotive components, such as the engine support, turbocharger body, gearbox, clutch housing, and steering box.

According to the European Automobile Manufacturer’s Association,

- Integration of advanced dispensing technology for enhancing efficiency and reducing waste - Various technological advancements are introduced in application methods such as robotic spray systems and advanced dispensing techniques which are used to improve overall productivity by reducing waste and increasing efficiency. After applying mold-release agents, the highest accuracy in robotic spray systems can be achieved.

Additionally, in order to maintain quality, increase the rate of productivity, and reduce the harmful effects on the environment in the manufacturing sector, robotic spray systems and state-of-the-art dispensing technology were used while applying mold release agents to aluminum die castings. These changes provide accuracy and sustainability of the die casting process.

According to the International Federation of Robotics, the

Challenges

- Strict regulations for environmental protection - Various solvent-based mold release agents contain volatile hydrocarbons and chlorofluorocarbons due to which the government has laid down strict regulations. These agents release VOC-rich vapours (volatile organic compounds) into nature. The government has introduced several laws which state the use and disposal of these mold-releasing agents. This will hamper the market growth of aluminum die casting mold release agents.

- Disruption in the supply chain due to improper management - There are various reasons including trade disputes, delays in transportation, and price fluctuations that can have a notable effect on the market growth of aluminum die casting mold release agents.

Aluminum Die Casting Mold Release Agents Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Year |

2026-2035 |

|

CAGR |

4.7% |

|

Base Year Market Size (2025) |

USD 325.47 million |

|

Forecast Year Market Size (2035) |

USD 515.2 million |

|

Regional Scope |

|

Aluminum Die Casting Mold Release Agents Market Segmentation:

Type Segment Analysis

Water-based segment in the aluminum die casting mold release agents market is expected to grow at more than 60% CAGR through 2035. These agents are formed by mixing water and active ingredients, the mixture created is less harmful, and non-toxic in nature as it releases fewer VOCs. Water-based solvents are simple to use and are cost-effective as they have a longer shelf life.

These agents are less expensive to transport and meet the majority of plant safety regulations. According to the latest report, there are 9585 import and export shipments globally of mold release agents in 2024. There are 1308 buyers and 1190 suppliers of mold release agents across the world. s

Application Segment Analysis

Application segment is predicted to hold over 40% aluminum die casting mold release agents market share by the end of 2035. The agents are used in several parts such as engines, structural parts, and chassis in the automotive sector. These agents ensure heat stability, reduce residual waste, and result in the smooth and efficient casting of aluminum components.

Industrial machinery manufacturers are also dependent on these agents to obtain high-quality casting for the types of equipment such as aluminum air battery used to increase energy density. Growth in the automotive components sector worldwide is set to drive the segment growth segment in the forecast period. According to the latest report published by the European Automobile Manufacturers Association, the total sales of new cars increased by 10% in 2023 after remaining stable in 2022 across the globe.

Our in-depth analysis of the market includes the following segments:

|

Type |

|

|

Application |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Aluminum Die Casting Mold Release Agents Market - Regional Analysis

North American Market Insights

North America industry is anticipated to hold largest revenue share of 35% by 2035. The market growth in the region is also expected on account of the increasing adoption of automation and intelligent manufacturing techniques.

The aim of these techniques is to create safer, effective, and harmless products. There are various sectors such as aerospace, automotive, and electronics that require highly accurate die castings due to which advanced manufacturing technologies are introduced in the region. The research and development sector focusing on technological advancements in the country is impacting the demand for aluminum die casting mold release agents that are compatible with these advanced systems.

The aluminum die casting mold release agents industry is growing significantly in the United States due to the growing rate of production and demand for aluminum-related products in different sectors. According to the Aluminum Association, the demand for aluminum in the United States and Canada (shipments by domestic producers along with imports) increased by 4.8% resulted in around USD 27.5 billion in 2022.

In Canada, various automotive manufacturers are using aluminum components and replacing steel components, which is leading to a higher demand for aluminum die casting mold release agents.

APAC Market Insights

The Asia Pacific region will also encounter huge growth for the aluminum die casting mold release agents market by 2035 and will hold the second position owing to population growth and urbanization. According to the United Nations Population Fund, 60% of the world’s population, or around 4.3 billion people live in the Asia Pacific region. Additionally, growing demand for smart cities, various industrial regulations, and global demand for die casting products are driving the growth of the APAC market.

The increasing demand for residential and commercial buildings in China along with the automobile sector is responsible for the market growth of aluminum die casting mold release agents. According to the latest report, the annual construction of commercial properties in China come to around 81.55 million square meters in 2022.

Growing demand for aluminum die casting agents in various sectors such as electronics, and increased production and sales of automotive vehicles in Korea are the reasons behind the development of the market. As per a recent report, there were 438 export and import shipments of die casting aluminum in South Korea, which are exported by 73 exporters to 85 buyers.

Aluminum Die Casting Mold Release Agents Market Players:

- Henkel AG and Company

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Merck KGaA

- FUCHS LUBRITECH GmbH

- Vesuvius

- Chem-Trend L.P.

- METAL FLOW SA

- ACMOS CHEMIE KG

- Quaker Chemical Corporation

- Lubrochem Srl

- The HILL

The major players in the aluminum die casting mold release agents market are offering high-performance and environment-safe casting molds which provide for sustainability, reliability, efficiency, and cost savings. These companies are developing and delivering aluminum die castings which are used in the automobile industry.

Recent Developments

- Chem-Trend L.P. recently introduced DilutionIQ System which helps manufacturers in various sectors worldwide to improve. This scope of improvement which is an innovative solution is introduced by a Michigan-based company.

- Merck KGaA presents cutting-edge pharma technology and electronic material production. It is going to be the world’s first modular production line based on new automation standards accelerating the manufacture of innovative materials.

- Report ID: 6124

- Published Date: Dec 01, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Aluminum Die Casting Mold Release Agents Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.