Posted Date : 18 September 2025

Posted by : Parul Atri

Imagine a world where you can style anything, be it from creating a prosthetic limb to a customized phone cover, right from your home. This sounds like science fiction, right? But, not anymore! The technology of 3D printing has emerged and has revolutionized the manufacturing, food, fashion, and healthcare production. Whether a tech scientist, a hobbyist, or even just curious about the newest advancements, 3D printing is something that everyone should be aware of.

In this blog, we will be covering the whereabouts of 3D printing, its operational activity, and what is in store for the upcoming future regarding this path-breaking technology!

Turning Digital Dreams into Reality with 3D Printing

What is 3D Printing?

Digitalization and advancements are at their peak, and one can only imagine being able to design something on personal computer systems at one time, and then holding it in their hands- no requirement of massive machinery and factories, it is just you and a machine that develops objects layer by layer. This is the power that 3D printing withholds, which is also referred to as additive manufacturing. In comparison to conventional methods that slice away material, just like sculpting a block from wood, 3D printing operates in a reverse way. Instead of carving out, it keeps on adding material in a precise way as per the need, thereby creating objects from scratch without wasting anything.

How Does 3D Printing Actually Work?

This usually comprises the following three simple, but mind-blowing steps-

- Designing the model: It all begins with a digital blueprint! Utilizing CAD software, such as Fusion 360 or TinkerCAD, or even a 3D scanner, one can scan and create a 3D model based on the desire to print. This can be a miniature statue of a pet or even a replacement gear.

- Slicing the model: The 3D printer does not understand the model as a whole; instead, it needs instructions. In this regard, specialized software, including PrusaSlicer and Cura, can be utilized to chop the design into hundreds or even thousands of ultra-layers that are thin and horizontal. This will effectively turn the 3D object into a stack of 2D slice.

- Printing the object: The real fun begins in this particular step. The printer primarily heats up the selected material, be it metal, resin, flexible TPU, tough ABS, or even PLA plastic. It then deposits on a layer-by-layer basis, by following the sliced design. After this process, slowly and steadily, the object will take the shape as provided.

Therefore, depending on the complexity and size, a print can take minutes or days for a small keychain or a detailed architectural model. But the best part lies in the fact that no two prints are exactly similar. Whether a hobbyist crafting cosplay props or an engineer prototyping the latest invention, 3D printing ensures the power to directly create anything.

The 4 Game-Changing 3D Printing Technologies

It is obsolete to think that all 3D printers are the same! Just like cars range from heavy-duty trucks to compact city runabouts, even different 3D printing technologies also serve numerous purposes. From being a maker crafting prototypes in a garage or an aerospace engineer developing rocket parts, there exists a perfect method of 3D printing for desired requirements. Now, let us dive into the four most revolutionary types of transformation:

Fused Deposition Modeling (FDM) - The People's Printer

Let’s picture a high-technology-based hot glue gun that has been precisely layered by melting plastic. This is what FDM caters to when in action! This particular 3D printing technology is the most widespread and cost-effective technology, which can melt plastic filament, including PETG, ABS, and PLA, through a heated nozzle that can create objects on the basis of layers. Besides, this technology is suitable for beginners, it comprises low-cost operation with existing materials and is appropriate for educational models, DIY projects, and functional prototypes. On the contrary, FDM cannot match with ultra-smooth finishes since multi-material and soluble support printing are the newest upgrades.

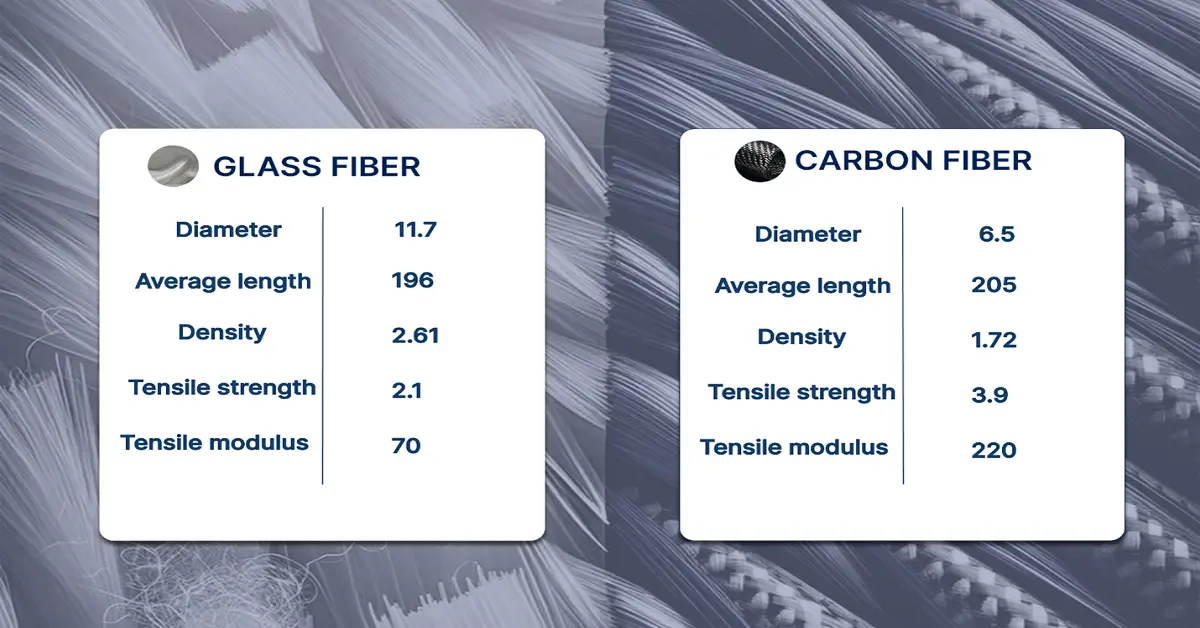

Moreover, as stated in the September 2021 China Journal of Aeronautics report, glass fiber (GF) and carbon fiber (CF) strengthen at least 5% of composite filaments, which are fabricated by utilizing a temperature extruder, along with an increased volume fraction, owing to differences in the density. These filaments are then 3D-printed in test samples by further utilizing a home-based and high-temperature FDM printer, with enhanced fiber content for augmented mechanical components.

Source: Science Direct

Source: Science Direct

Stereolithography (SLA) - The Detail Master

These 3D printers work like magic since they comprise a laser beam that dances across a tank of liquid resin, which hardens it into an exquisite solid form with microscopic precision. The result, in turn, leads to smooth details and surfaces. This particular 3D print is readily utilized by jewelry designers who create intricate pieces, dentists who craft picture-perfect aligners and crowns, and last but not least, artists who produce gallery-worthy sculptures. Besides, one appealing fact is that the existence of detailed miniature figurines are created by SLA printing.

Selective Laser Sintering (SLS) - The Industrial Powerhouse

SLS, in general, turns a laser welding powder into solid nylon or metal parts. It utilizes unsintered powder as natural support, in comparison to other printing methods that require support structures. The ultimate objective is to permit incredibly complicated geometries. SLS printing is a game-changer for industries, for example, the aerospace sector that requires components to sustain extreme weather conditions, followed by durable end-use industrial parts, and customized medical prosthetics and implants. Besides, a few airplane cabins currently comprise SLS-based printing components that are strong and light when compared to conventionally manufactured parts.

Digital Light Processing (DLP) - The Speed Demon

DLP operates in a similar way to SLA, but there is a twist! It utilizes a digital light projector instead of a single laser to cure entire layers at once. This results in blazing fast print speeds without the need to sacrifice any details. This printing method readily excels in fast prototyping, especially during severe timelines, dental laboratories producing numerous crowns in a batch, and research institutions requiring rapid iterations. DLP has a promising future since it can print complicated and twisted objects in minutes rather than hours.

Based on the above-mentioned 3D print types, it is essential to choose the perfect match. From FDM’s cost-effectiveness to SLS’s industrial might, each technology caters to exclusive possibilities. All of these methods are gradually continuing to evolve, thereby producing unusual hybrids and advancements that can blur the lines between them. Besides, it is recommended for beginners to commence with FDM to gain insight and eventually explore SLA to print fine details. Therefore, the 3D printing revolution is not underway; it actually exists, and these four technologies are deliberately leading the charge.

How 3D Printing is Reshaping Our World?

There exists a common notion that 3D printing is all about making simple plastic toys! This revolutionary technology is readily breaking such barriers across various industries in every possible way that seems to be science fiction-based. At present, there are five astonishing industries that are being transformed by additive manufacturing.

Healthcare Revolution: Printing Body Parts

The medical sector is undergoing the biggest leap, owing to the presence of antibiotics. Organizations, such as UNYQ, are effectively creating customized prosthetic limbs that perfectly fit patients at a fraction of conventional expenses. In addition, dentists can easily print aligners and crowns in-office while patients wait during appointments. But the real game-changer is bioprinting, through which scientists have magnificently layered live cells to develop fully functional organs and skin grafts.

Aerospace and Automotive: Lighter, Faster, Stronger

SpaceX and NASA make use of 3D printing to produce rocket engine parts that can withstand severe space conditions, while diminishing weight by an estimated 52.5%. Organizations in the automotive industry, including Bugatti, tend to print titanium brake calipers. Besides, certain enthusiasts in this particular sector can restore classic cars with faultless replica parts that are impossible to find in general.

Fashion Forward: Wearable Innovation

The fashion runway has ultimately come across robotics with 3D printed haute couture, that is, dresses constituting movable parts. For example, Adidas' Futurecraft 4D shoes have readily implemented 3D print technology and feature midsoles printed to ensure similarity with the foot’s pressure points. Likewise, jewelers can craft incredible geometries that conventional methods are unable to replicate. Meanwhile, artists, such as Iris van Herpen, have created gravity-defying wearable art with the implementation of 3D print.

Construction Disruption: Houses in Hours

Key companies, including ICON, have the capability to print an entire home within a day for an estimated USD 15,000. This is possible with the utilization of special concrete in the form of the 3D print technology. Besides, it has been aimed in Dubai that almost 30% of its buildings will be 3D-printed by the end of 2030. This caters to architects pushing boundaries with waste-free and organic designs that were formerly unbuildable.

Culinary Alchemy: Food at the Click of a Button

The concept of 3D-printed food is readily revolutionizing presentation and nutrition from customized vitamin-driven meals for astronauts to complex chocolate sculptures. Startup firms, such as Redefine Meat, are gradually involved in printing plant-based steaks with realistic marbling.

Therefore, the use of 3D print technology in all the above-mentioned sectors is just the beginning of a new era. As there are advancements in printers and materials, these printers are poised to tackle challenges that one has ever imagined as of now. However, the question that remains is not what can we print, but should be printed!

The Next Frontier: 3D Printing's Jaw-Dropping Future

The 3D print evolution is just getting started, and what is ahead is just beyond imagination! From running shoes to dental implants, everything that people own will instantly be personalized to their absolute body measurements. There will be the absence of one-size-fits-none compromises. Besides, 4D printing is also set to make a debut, wherein furniture can readily assemble itself, and expand as well as contract based on temperature conditions. Regarding this, research is undergoing at MIT, where researchers have already developed materials that tend to transform over time when exposed to light, heat, and water.

Moreover, with the widespread utilization of the 3D print technology, there will be the end of traditional factory facilities. This will result in the non-requirement of welding in a thousand parts, when manufacturers can print based on demand. Meanwhile, automotive firms are readily converting to 3D-printed car components, which can reduce waste and expenses dramatically. Likewise, NASA is working on systems and devices, wherein autonomous robots will deliberately 3D-print the entire lunar base. This will turn into reality by integrating moon dust just prior to the landing of astronauts. It might even be possible to print a Mars apartment in the near future!

Final Thoughts

The revolutionized concept of 3D print has readily exploded from science fiction to world-changing reality, denoting just the opening chapter. The world is witnessing a manufacturing renaissance wherein astronauts, architects, and hospitals are printing their required products. The technology has a true power which lies in its democratization, and at present, anyone can invent the future from a remote location with an estimated spending of USD 250 on printers. Besides, materials are also evolving from graphene to bio-inks in this revolutionary era. Therefore, there are ample options to customize life-saving medical devices, fashion, and something else that anyone has ever dreamt of.

Contact Us